Hydraulic Valve Test using CompactDAQ and LabVIEW

Overview

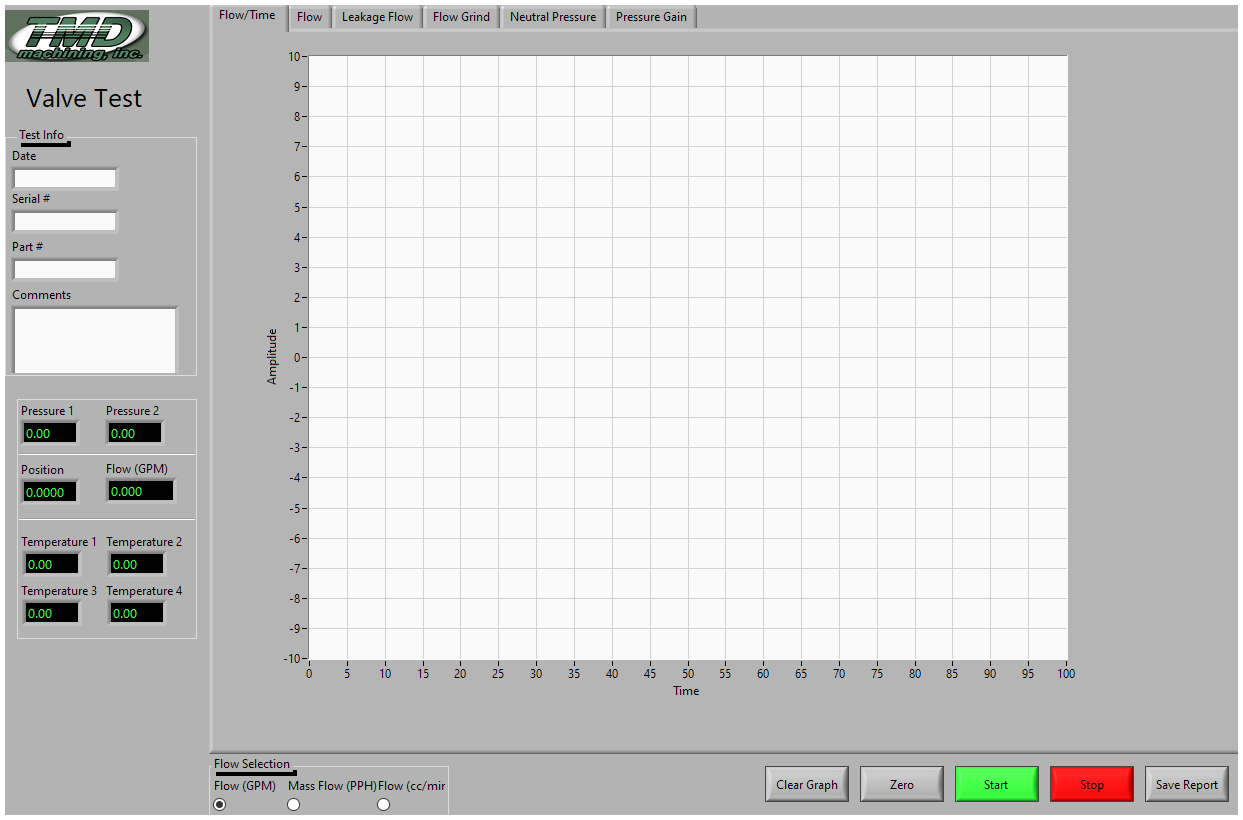

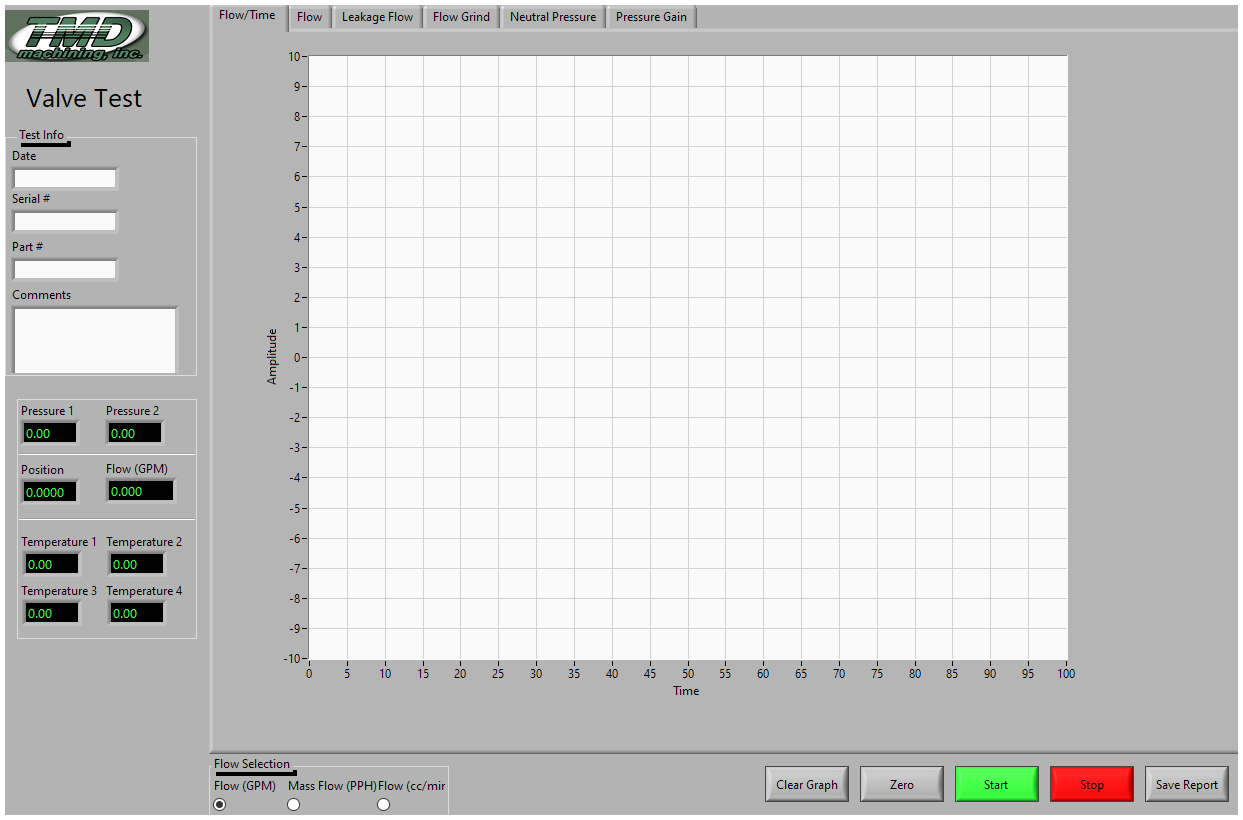

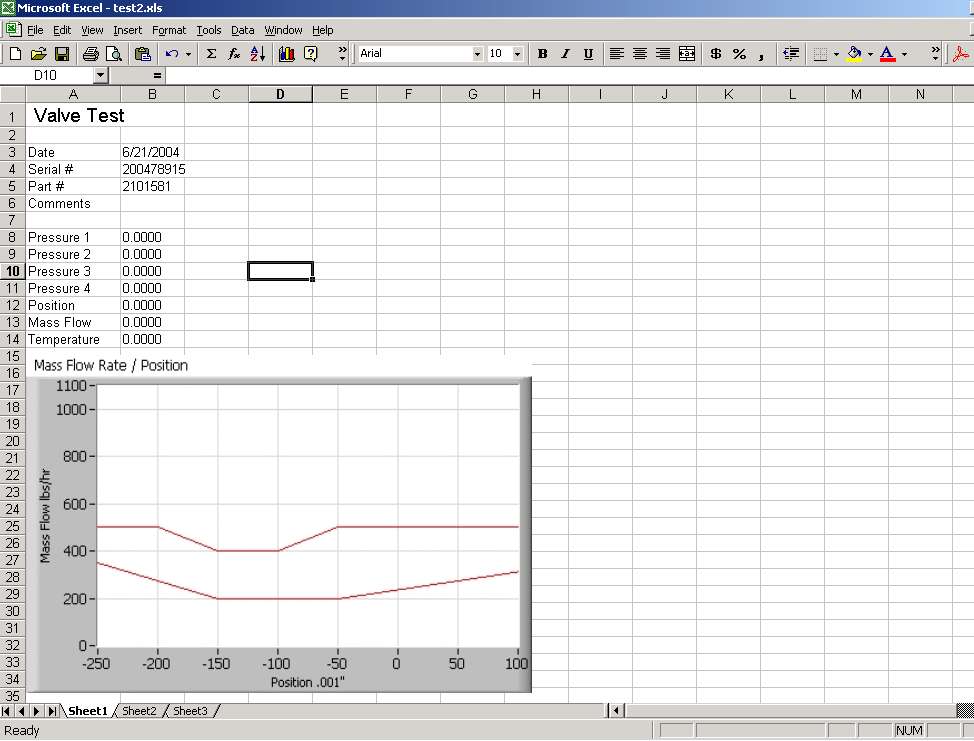

Hydraulic Valve Test using CompactDAQ and LabVIEW. A precision machine shop was building a test stand to test precision valves for an aerospace application. They needed data acquisition software that could monitor valve position, mass flow of the fluid, fluid temperature, and fluid pressure. The software needed to graph mass flow rate vs. position and pressure vs. position respectively. They also needed the capability to save reports containing the current readings of the sensors and screen shots of the graphs.

Solution

Hardware

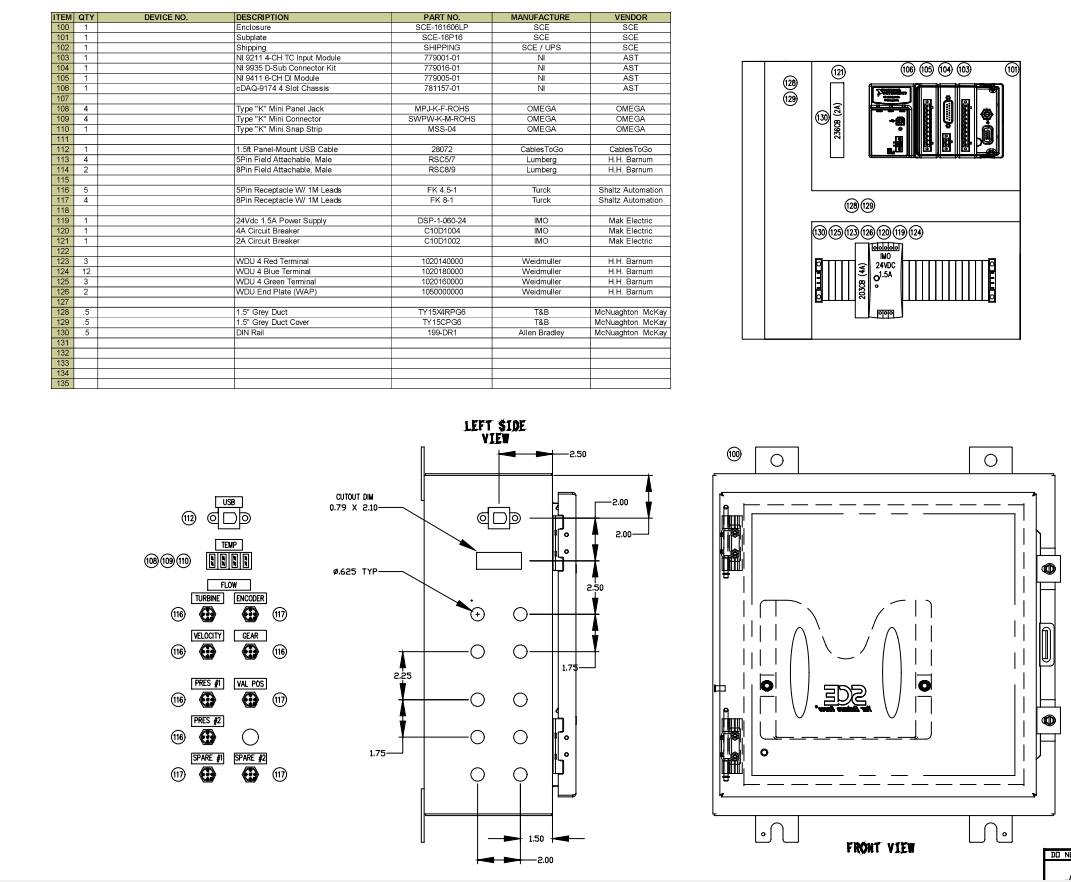

We used NI CompactDAQ to interface with all the sensors. CompactDAQ is a modular data acquisition hardware platform that allows for data I/O with LabVIEW software to enable engineers to collect, process and analyze sensor data. A CompactDAQ system can connect to a PC via USB or Ethernet. CompactDAQ has different modules that allow to connect to different types of sensors. For example an Analog Input Module was used to connect the sensors that used a voltage signal. A thermocouple module was used to connect to the thermocouples.

Example of CompactDAQ system

Enclosure

We also made a custom enclosure to house the CompactDAQ hardware and power supplies for the sensors. We put standard connectors on the outside of the enclosure to enable easy connection. Full CAD wiring diagrams were provided.

Enclosure Drawing

Software

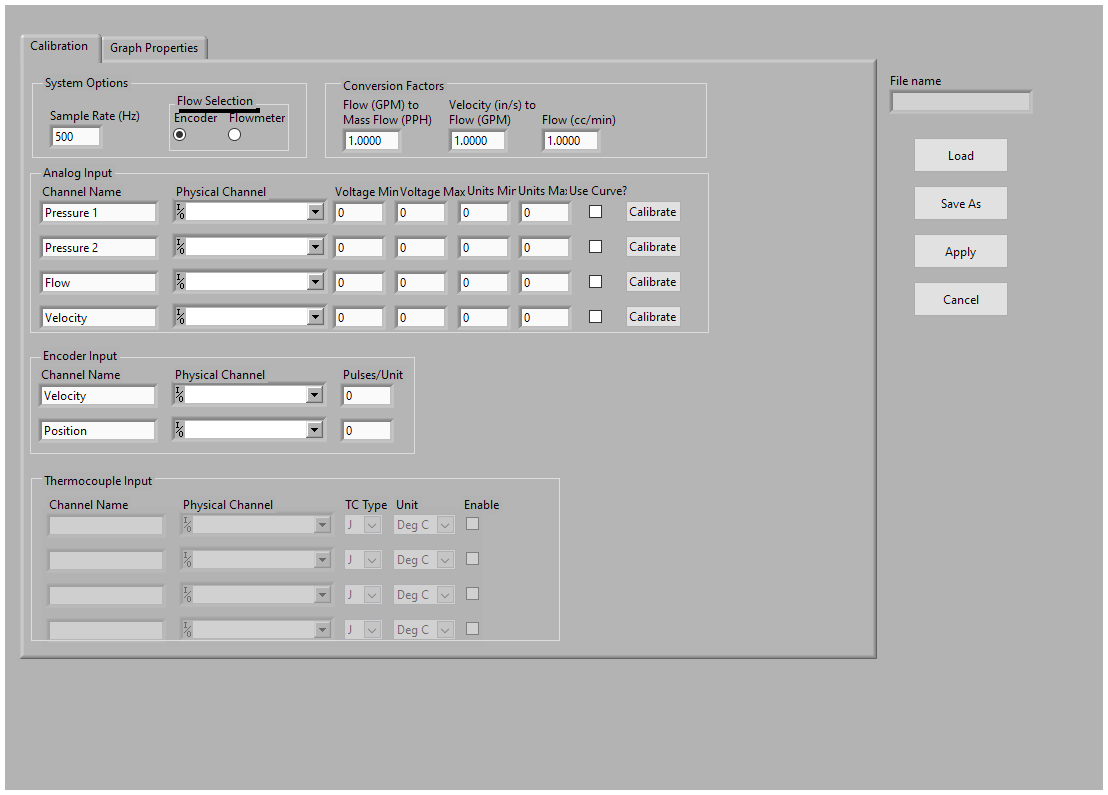

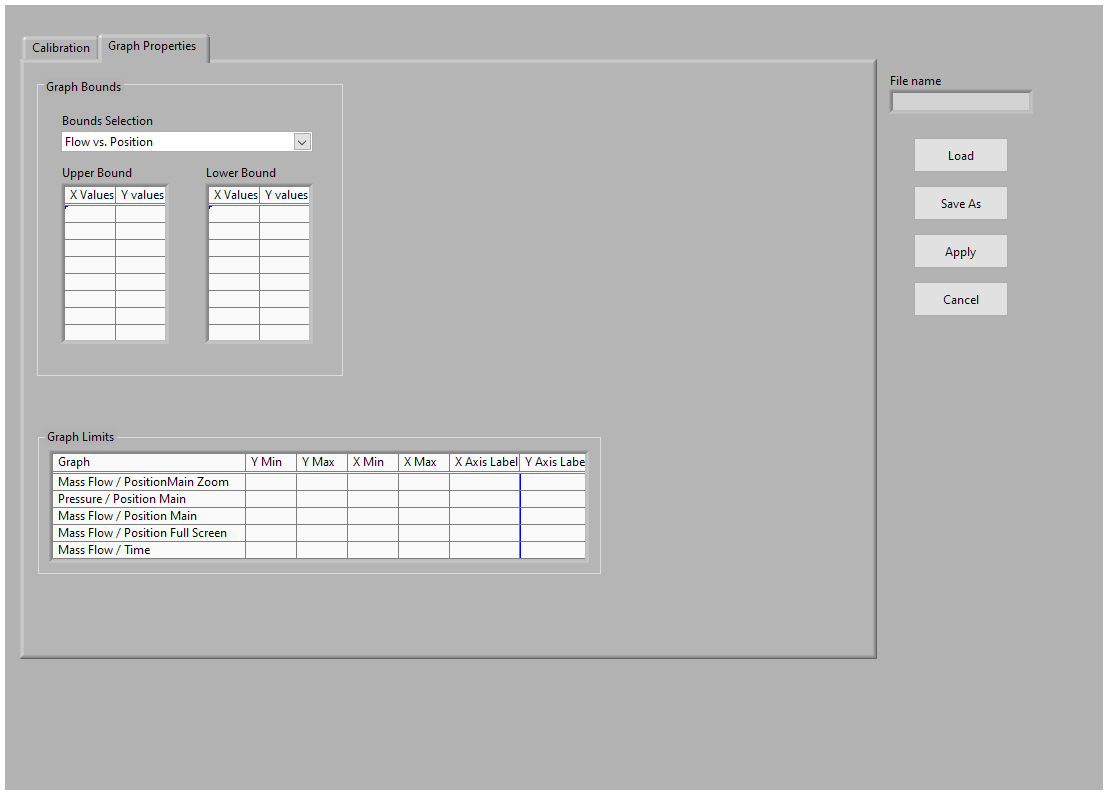

We developed a custom LabVIEW program the met all of the above requirements. The program we developed contained a user interface that was intuitive for the operator and easy to use. An advanced option menu was created so the user could enter upper and lower bounds on the graphs. This was done so the operator could easily determine if the valve was operating under acceptable conditions. The user could also save the profiles created and load them in at a later time. We also created tabs that contained full screen graphs of the data of interest.

Features

Advanced Options

Report

Result

The software we developed enabled the machine shop to quickly, and economically test the valves that they produced. It saved them countless time, and money due to the fact they could test the valves in house and not have to send them out to be tested. They were also able to attach easy to read reports of the valves they sent out proving that they operated within accepted tolerances.

Let's build an application together. Contact us today

- Learn how we do a project

- Lean about PC based data acquisition

- Learn more about CompactDAQ

- Learn more about LabVIEW

- Learn about other test systems we have done for other customers