Data Logger using CompactDAQ and PCI

Overview

Data Logger using CompactDAQ and PCI. A research and development company needed a system to monitor their automated material dispensing system. The measurement system needed to monitor pressure, flow, and digital signals from a robotic dispenser. The software was required to work with hardware the customer previously owned along with modern USB data acquisition hardware. The customer also wanted the same software to view the acquired data.

Solution

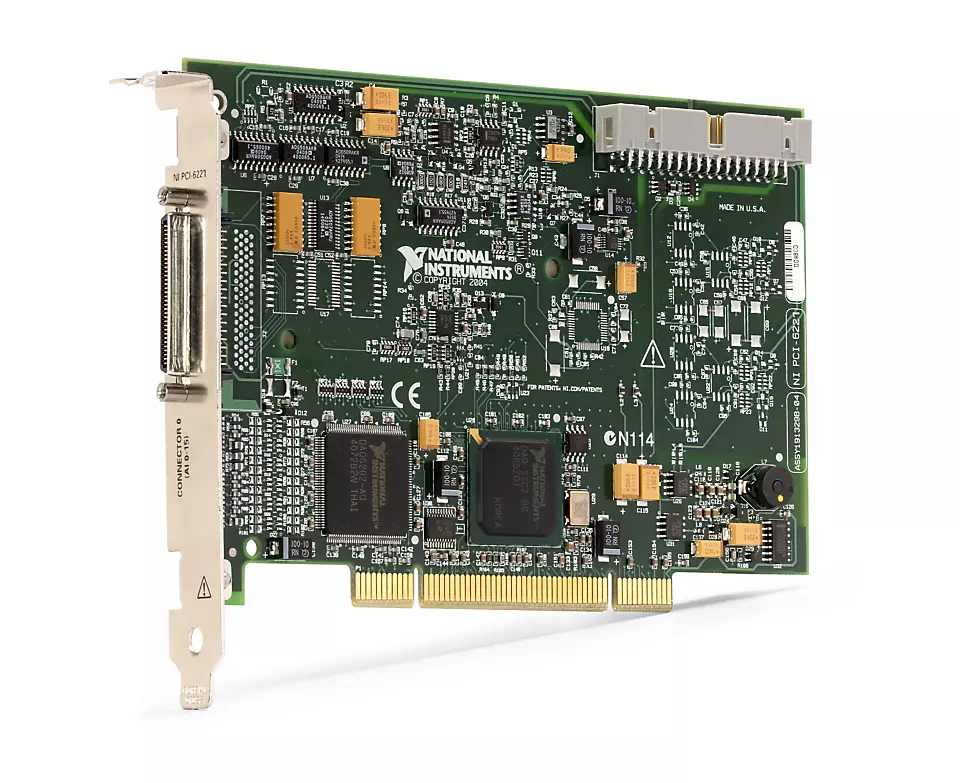

We developed a custom program written in LabVIEW that could monitor all the signals of interest. The software could work with a variety of National Instruments' hardware (

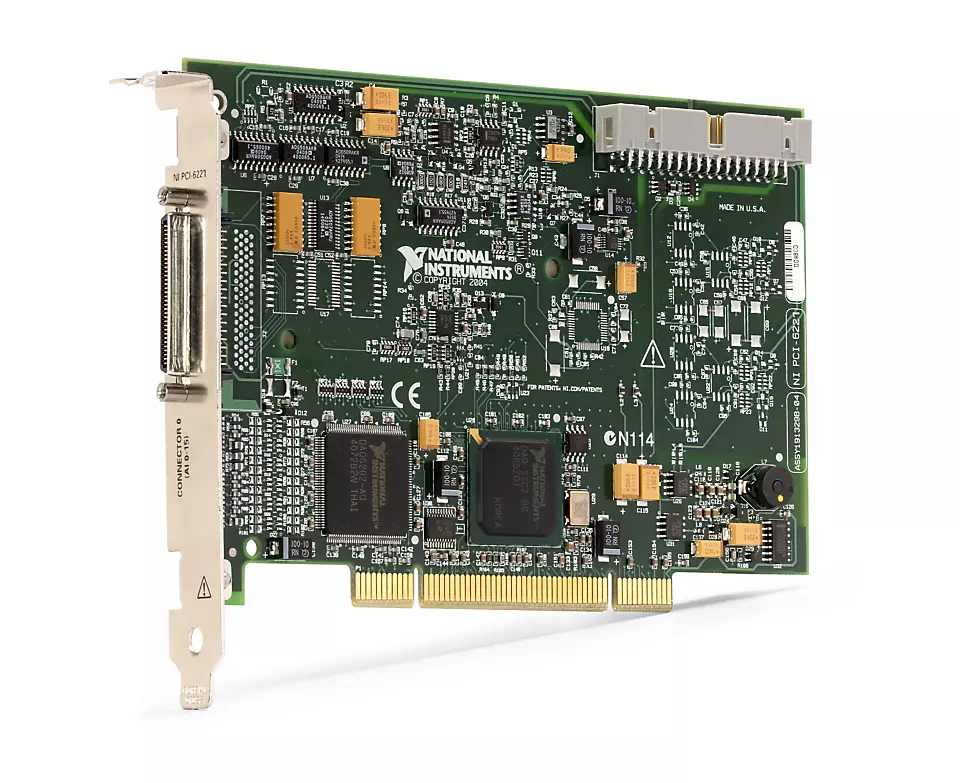

PCI data acquisition cards and

CompactDAQ USB hardware). This allowed the customer to use their existing NI hardware along with newly purchased upgraded hardware. The software was also capable in operating in "viewer" mode. If hardware was not detected the software could load and analyze previously acquired data. The viewer mode functionality was useful for managers and engineers who needed to analyze the acquired data.

This software allowed the customer to use the same tool to acquire and analyze data in multiple locations. We provided help files and extensive documentation to reduce training time and make the software very easy to use.

NI CompactDAQ

NI PCI Multifunction DAQ Card

Features

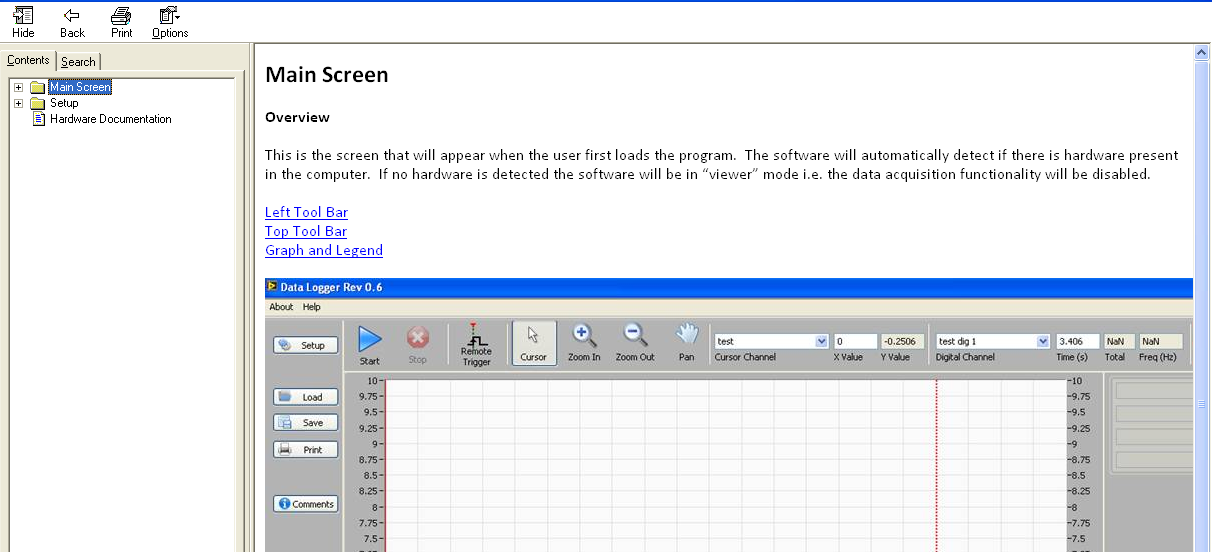

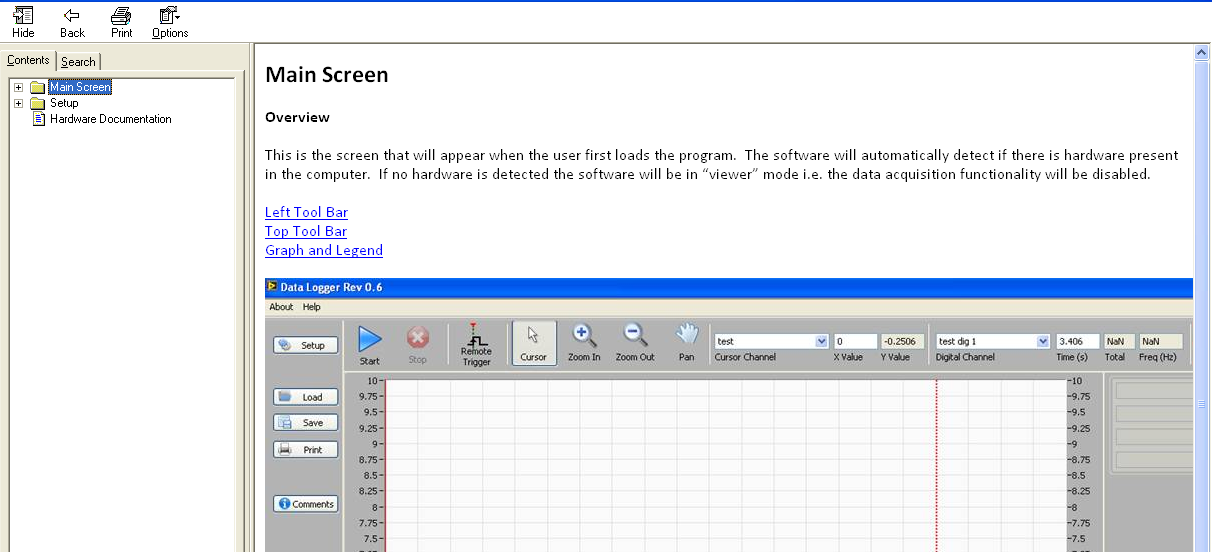

Main

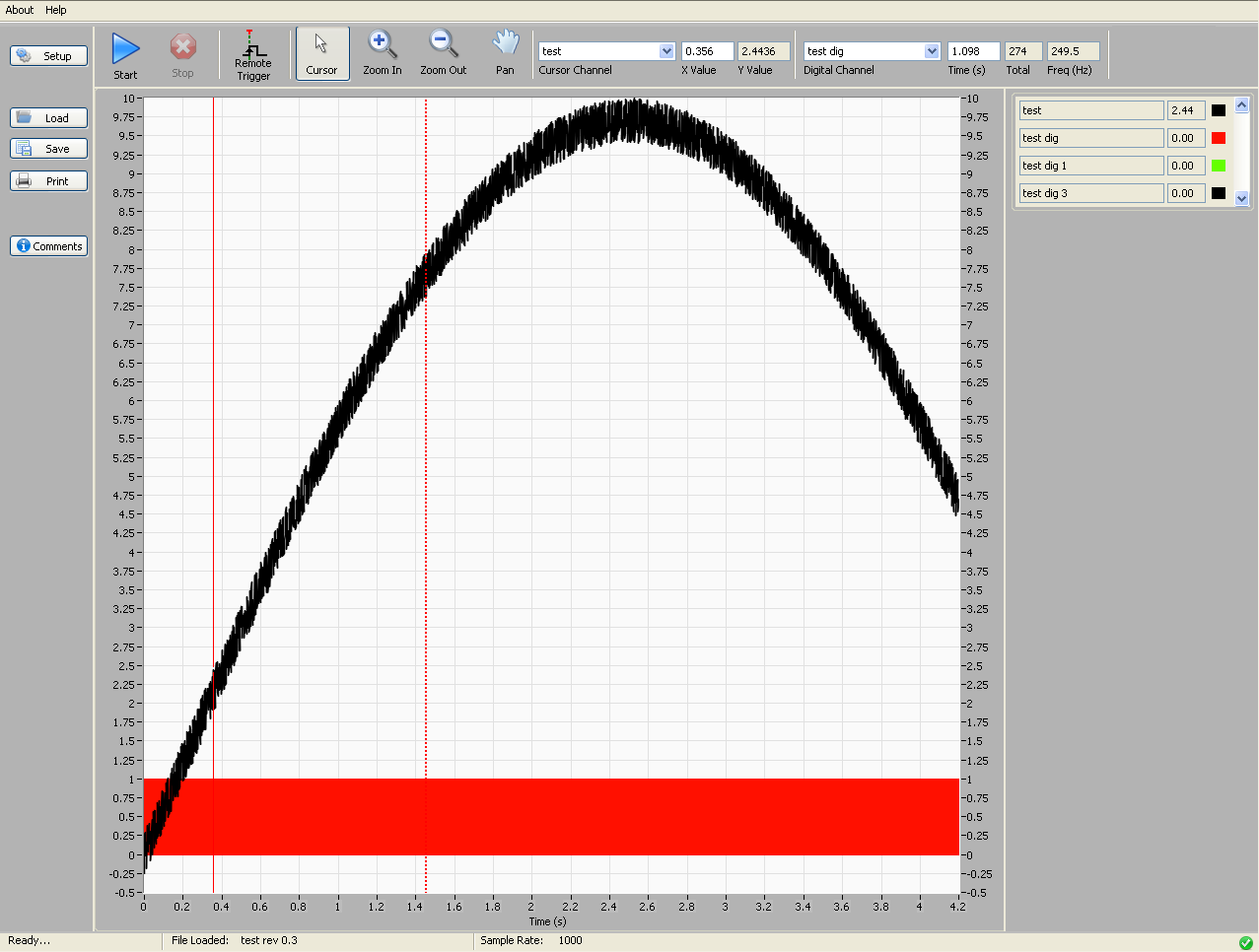

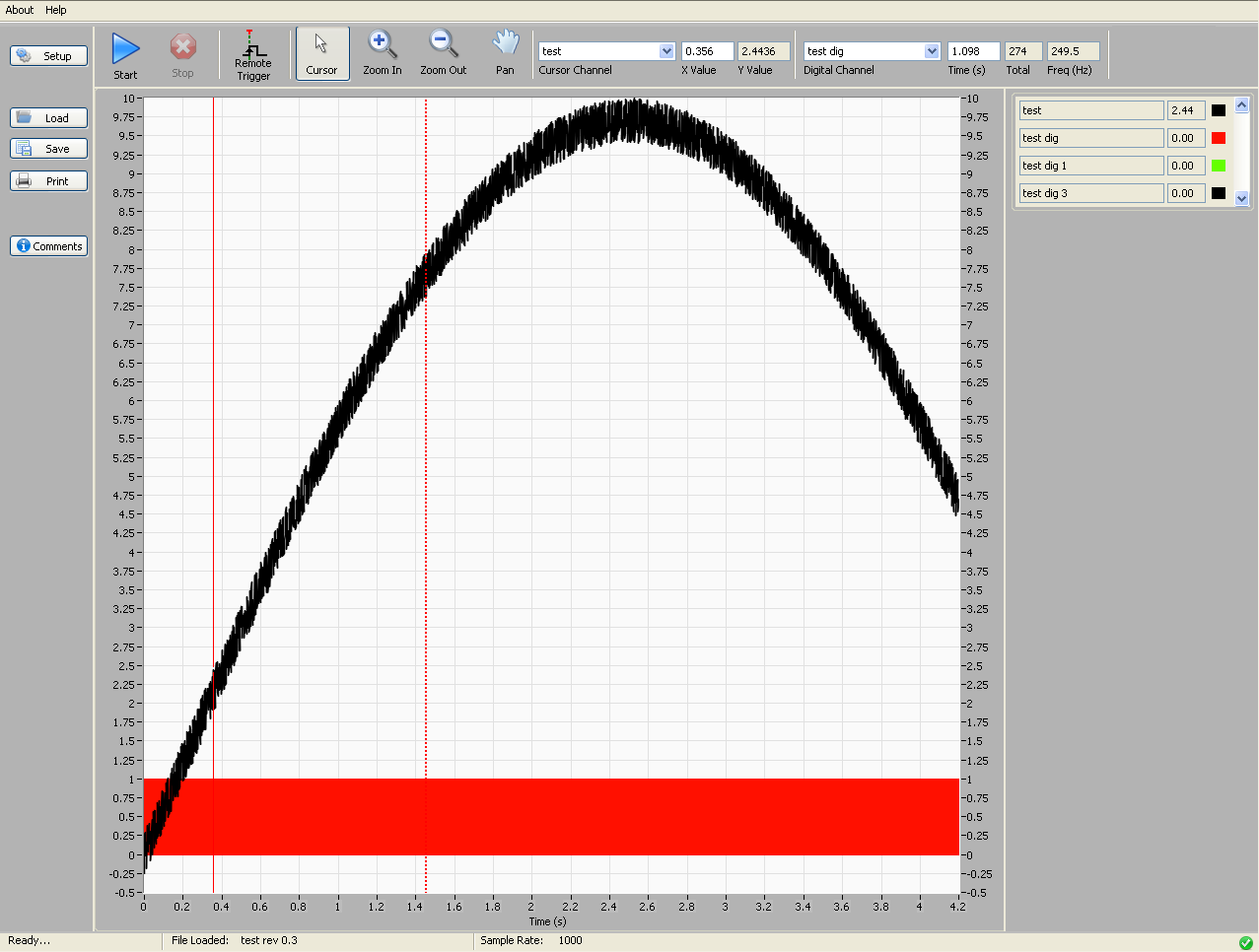

The main screen allowed the user to acquire and analyze data from the test. The user could load previously saved acquired data for analysis. The user could start and stop acquiring data. Analysis features were added so the user could zoom in and out and pan the data displayed on the graph.

A cursor feature was added so the user could select a channel of interest and move the cursor to the point of interest. A numeric indicator of the X Y cursor position was displayed. The user could also select a digital input channel and get the frequency and number of peaks between the cursors.

A plot legend was available. The user could change the color of the plot and see the current value of the data.

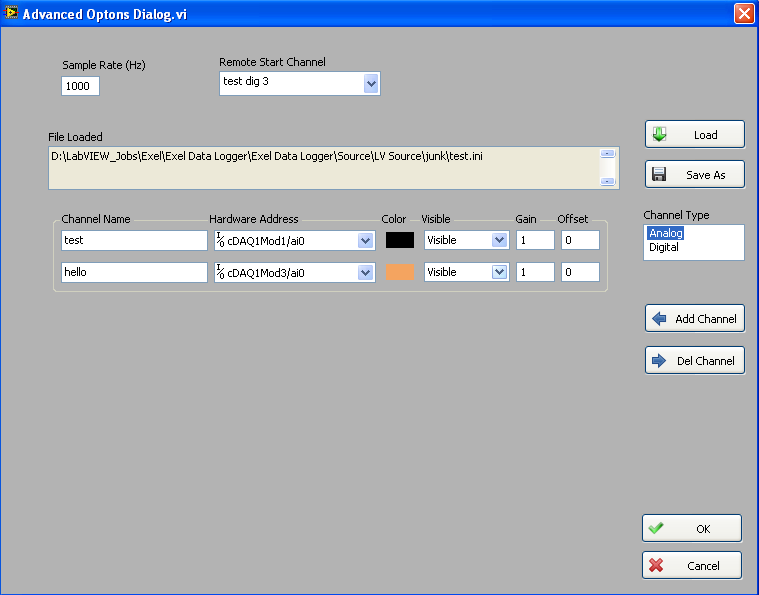

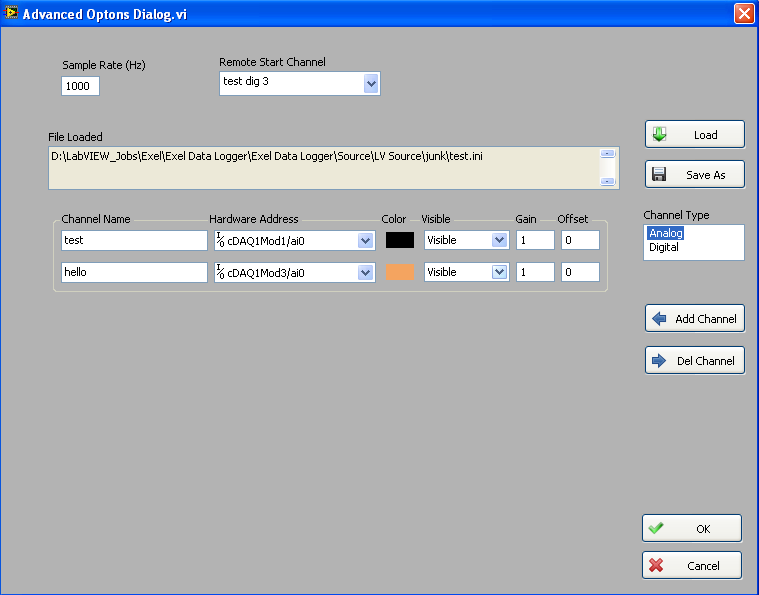

Advanced Options

The Advanced Options screen is where the user sets up program properties. The user could load and save different test setups. The user could also set the channel name, physical channel of the hardware, and calibration information.

Comments

The comments dialog allowed the user to enter test information that was saved to the data file

Help File

This is the help system provided with the software. Screen shots and detailed descriptions for all functions were provided. We also provided manuals of all the hardware used in the system.

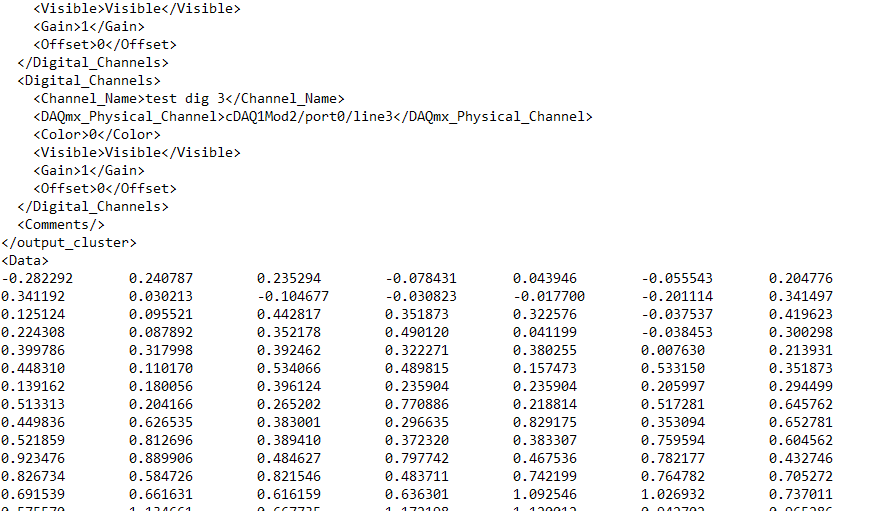

Test Data

Data from the test was saved as an xml file. This is a human readable data format. The software could read this file and display the data on the graph.

Result

Data Logger using CompactDAQ and PCI met all the requirements for the customer. The software was easy to use and allowed for different types of hardware to be used for acquiring data. The viewer tool allowed the user to load previously saved data and perform analysis. The ability to acquire and analyze data allowed the customer to verify their product and help make the design better. The software could be deployed in multiple locations. This allowed the entire company to use the same software to acquire and analyze data.