Medical Device Battery test using SMBus

Overview

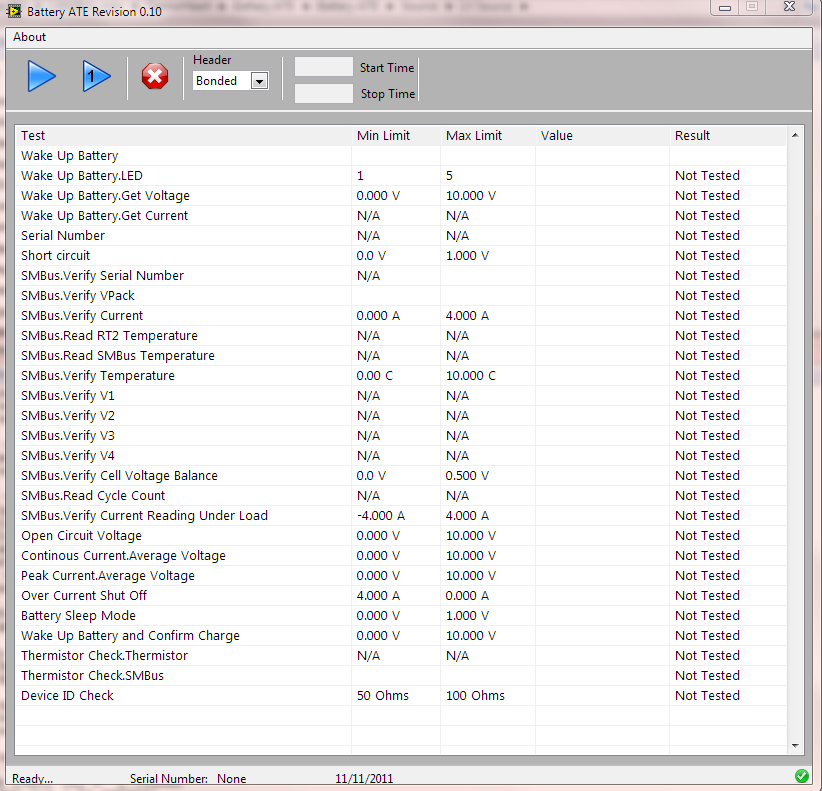

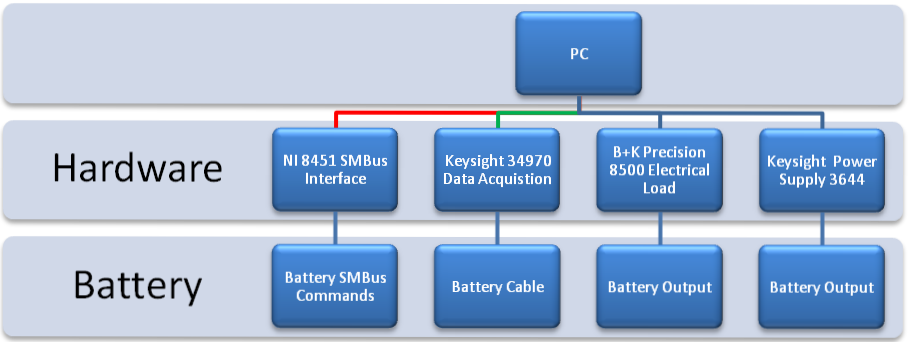

Medical Device Battery test using SMBus. A medical device company needed a system to automatically test a battery that powered various medical devices. The software had to use existing Keysight instruments, and communicated to the battery under test via SMBus. The software needed to be simple to use and needed to generate a printed report for quality and regulatory purposes.

Solution

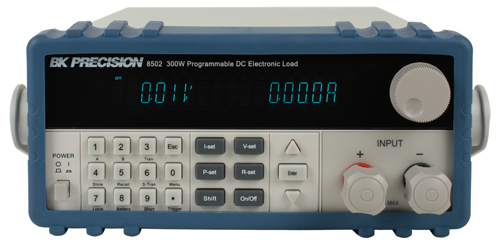

We developed a program in LabVIEW that automatically tested the battery. Using the existing Keysight 3490 Data Acquisition Unit, the Keysight 3644 Power Supply and the BK Precision 8500 Electrical Load we were able to use already calibrated and approved measurement devices. This saved the customer from validating new measurement hardware. Validating hardware used in medical device testing is very rigorous. Using already validated hardware save the customer an enormous amount of time and money.

BK Precision 8500 Programable DC Electrical Load

Communication from the PC to the instruments was done using GPIB and USB. GPIB stands for General Purpose Interface Bus. This bus is used on a lot of test and measurement hardware and allows the hardware to be connected to a PC. NI has an extensive library of LabVIEW GPIB drivers that can communicate to hundreds of instruments.

NI USB GPIB

SMBus was used to communicate to the battery under test. The System Management Bus (SMBus) is more or less a derivative of the I2C bus. The main application of the SMBus is to monitor critical parameters on PC motherboards and in embedded systems. We used a NI USB-8451 I2C/SPI Interface device that communicated to the PC via USB.

NI USB-8451

Features

Upper Voltage Limit (V) = "1"

Lower Voltage Limit (V) = "0.0"

Wait Time (s) = "2.000000"

Result

Let's build an application together. Contact us today

- Learn how we do a project

- Learn more about LabVIEW

- Learn more about Instrument Control