Automotive Side Mirror Functional Test

Overview

An automotive supplier that manufactures side mirrors needed to upgrade their automated mirror testing station. The previous software required the operators to analyze the data from each run using a cumbersome software tool and transfer the results to a hand written report. The user interface wasn't intuitive, and required the operator to do a lot of manual set up. The operator also had to do a manual analysis to determine if the mirror passed or failed the test. Finally the data from each run could not be saved for later analysis.

Features

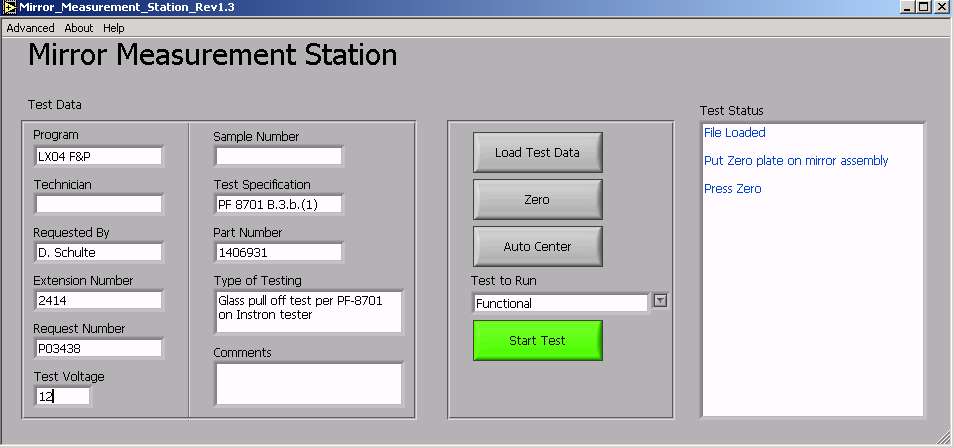

Main Screen

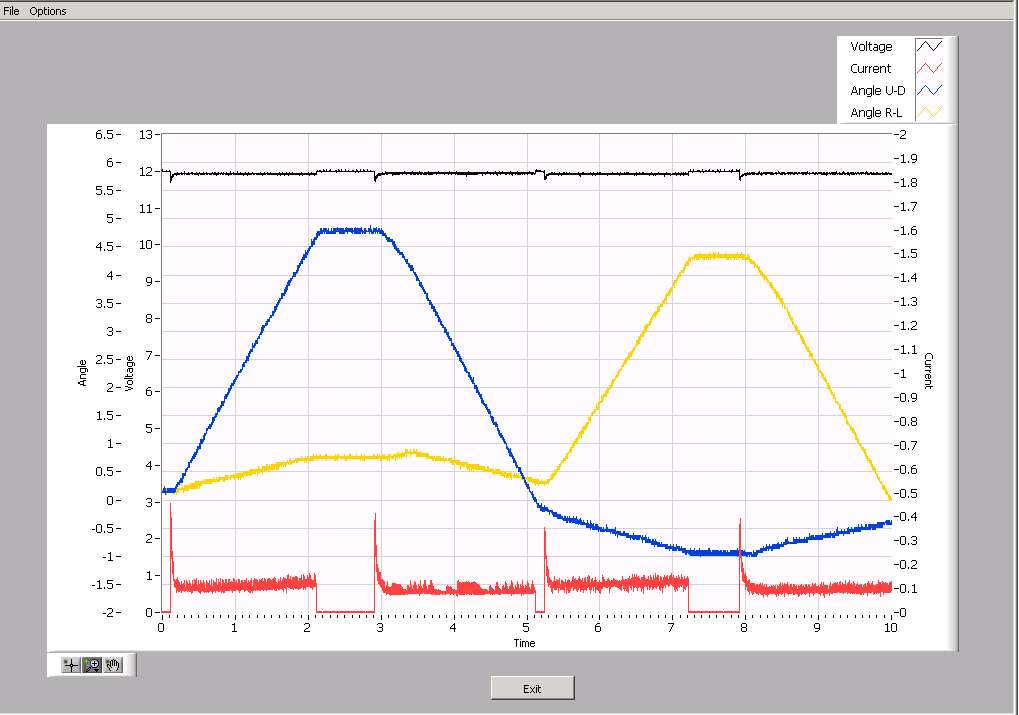

Graph

Report

Results

Using our software, the supplier greatly decreased the time it took to run a test. The automatic report generation saved vastly increased efficiency because the operators were no longer required to manually analyze and report test data. The ability to review the raw data of any previously run test helped the supplier diagnose problems that would have previously been impossible.

Let's build an application together. Contact us today

- Learn how we do a project

- Learn more about Data Acquisition

- Learn more about LabVIEW

- Learn about other test systems we have done for Automotive Customers