Automotive Flow Lab Monitoring and Control System

Photo Courtesy AVL not actual system

Overview

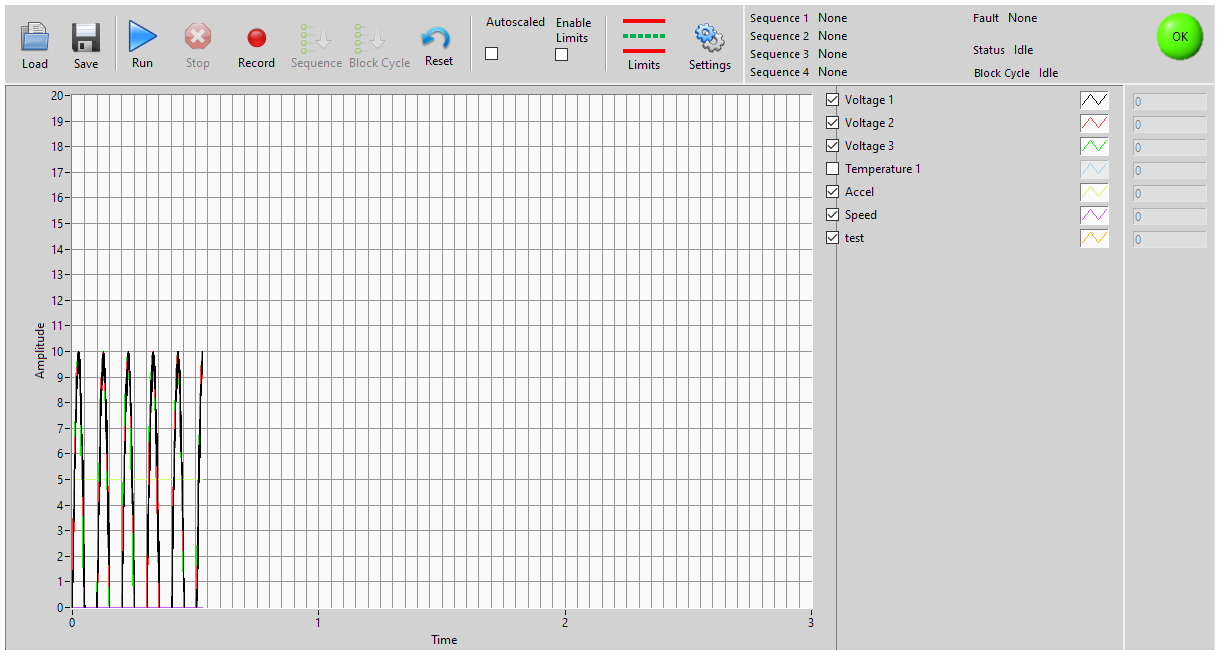

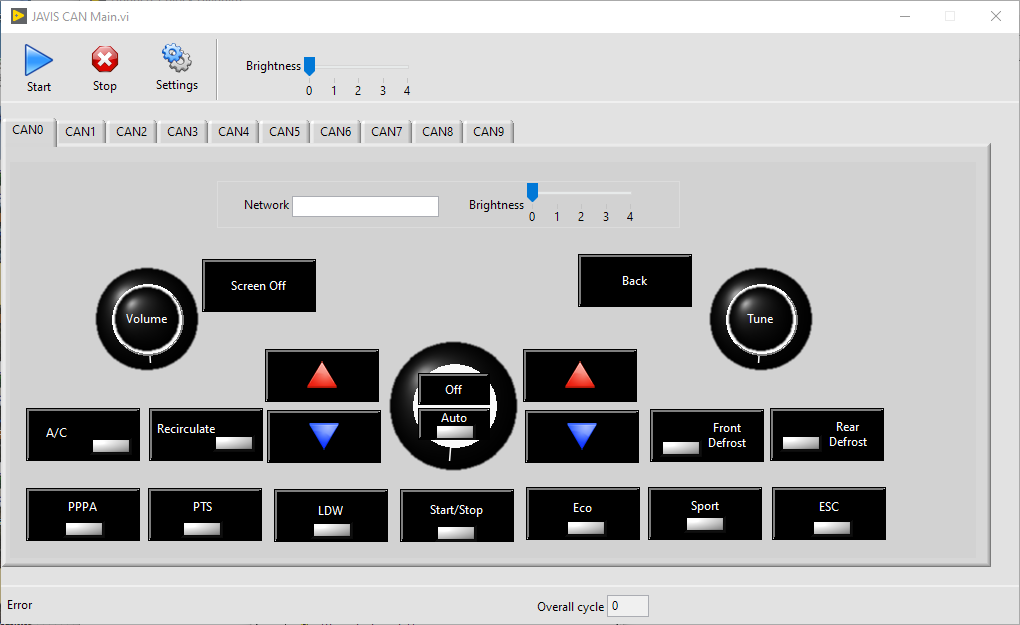

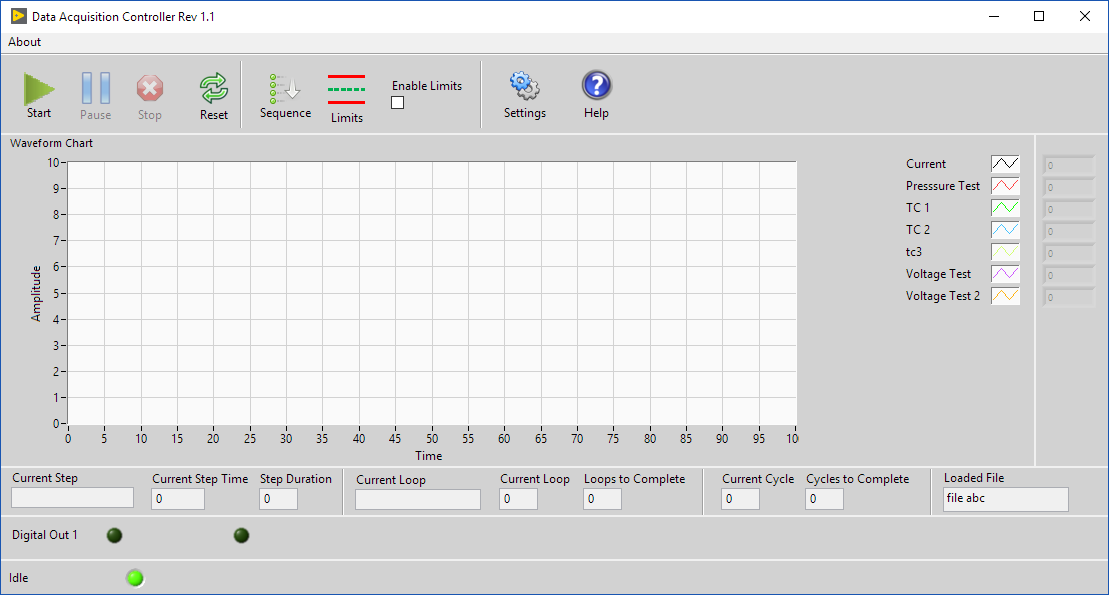

Automotive Flow lab Monitoring and Control System. A tier one automotive supplier of exhaust systems needed to upgrade their flow lab. The flow lab measured air flow through the part under test as well as various temperatures, and pressures. The software needed to monitor multiple instruments and sensors used to test the part. The software also needed to control a high speed blower, and a heater. The user interface needed to be intuitive to the operator and display and save the relevant data.

Read more …Automotive Flow Lab Monitoring and Control System