Brake Hysteresis Test using CompactDAQ and LabVIEW

Overview

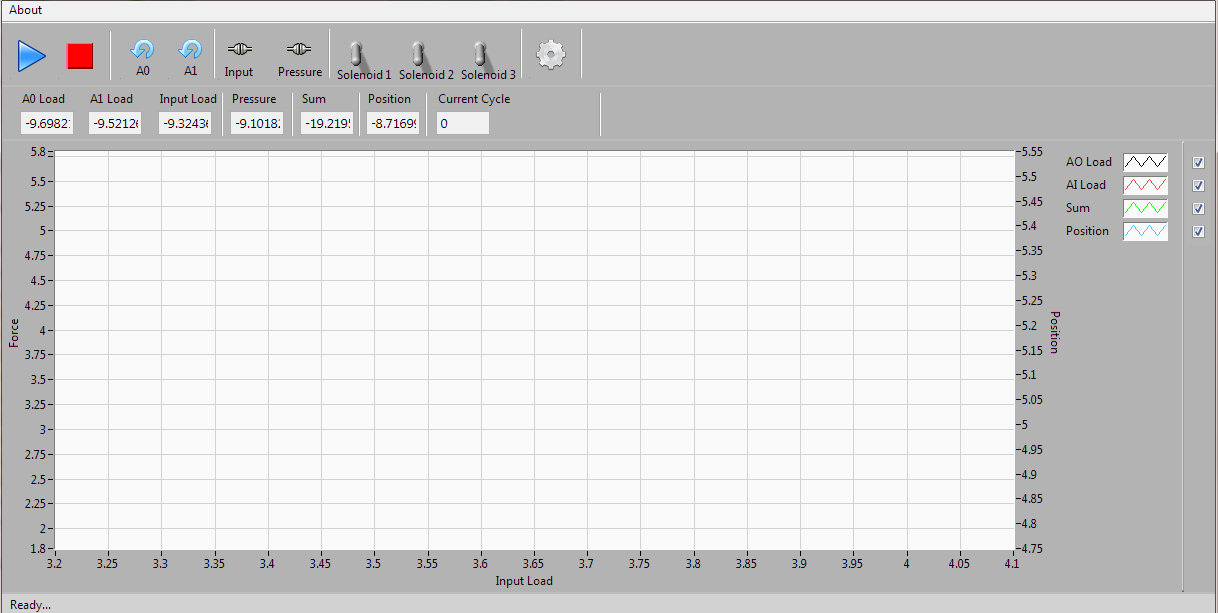

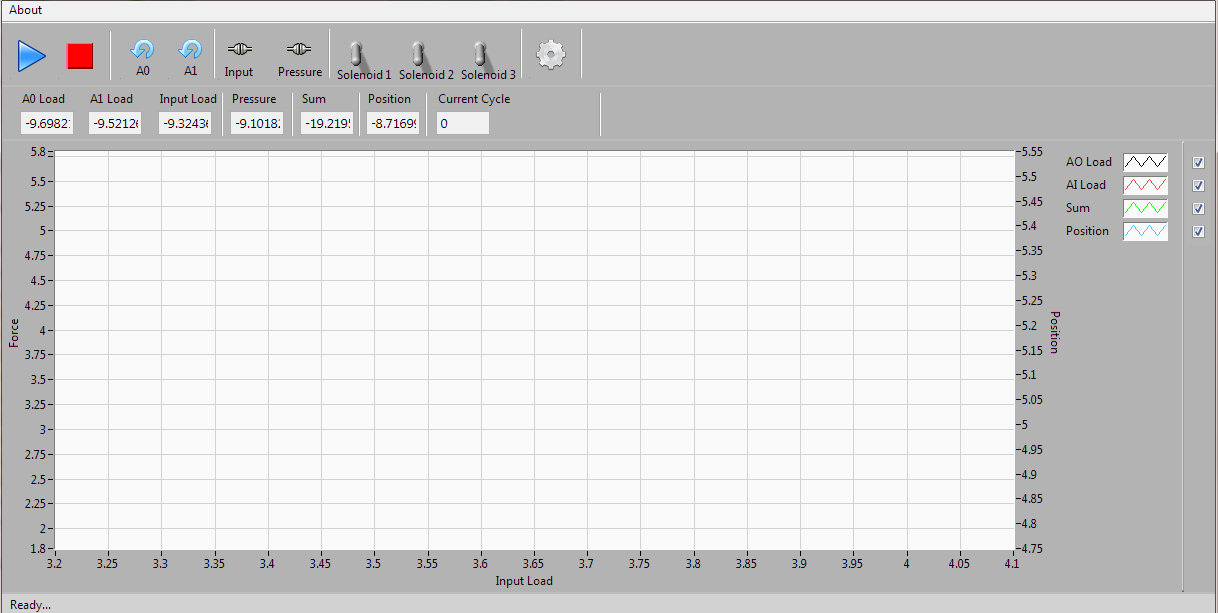

Brake Hysteresis Test using CompactDAQ and LabVIEW. An automotive lab needed a program to perform brake testing. The system had to acquire data from multiple load cells, control solenoids, and activate load cell shunts. The software had to plot force and position on an XY graph. The customer also needed a real time numeric display of the measurements and save the data to a predefined excel template.

Solution

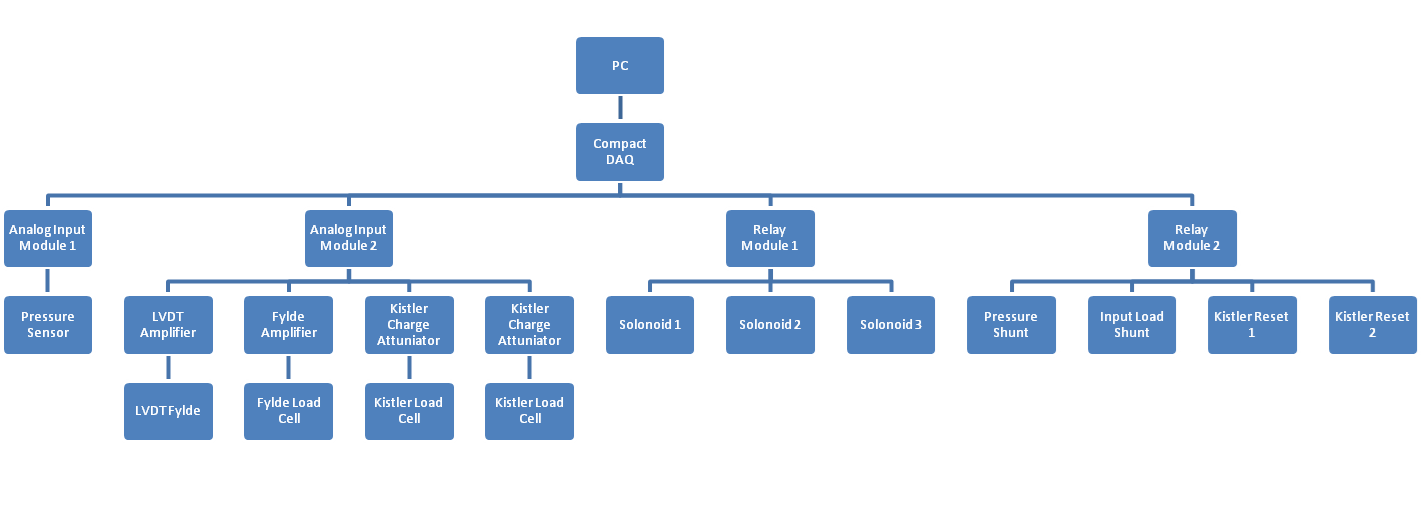

We used NI CompactDAQ data acquisition hardware to connect the sensors to the PC. CompactDAQ was chosen because it is a modular hardware platform that can accommodate various sensor types.

NI CompactDAQ

Block Diagram

We developed a program that allowed the operator easily captured the data of interest. From the front panel the operator could start and stop a test, reset sensors, and manually actuate solenoid valves. The operator could also turn the visibility of a plotted data channel on or off.

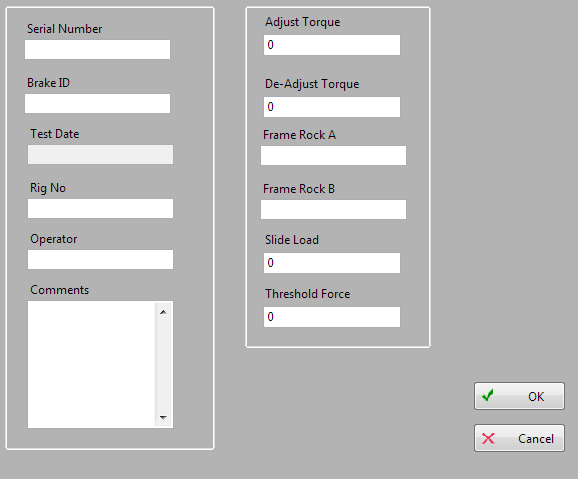

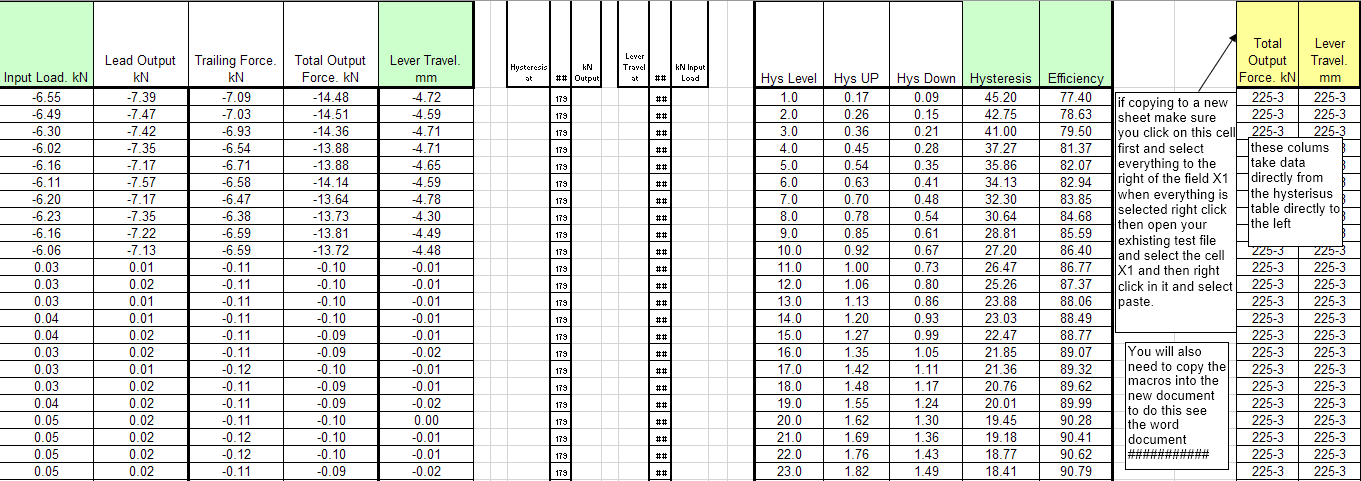

The software populated the collected data into a customer defined excel template. The customer could choose the template to use from the advanced options in the software. Using a template, the customer could easily change how the data was processed and displayed.

Features

Main Screen

Start Dialog

Advanced Options

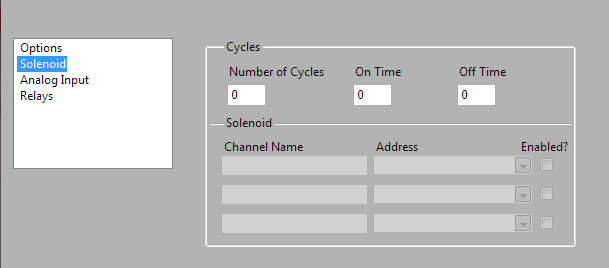

Solenoid

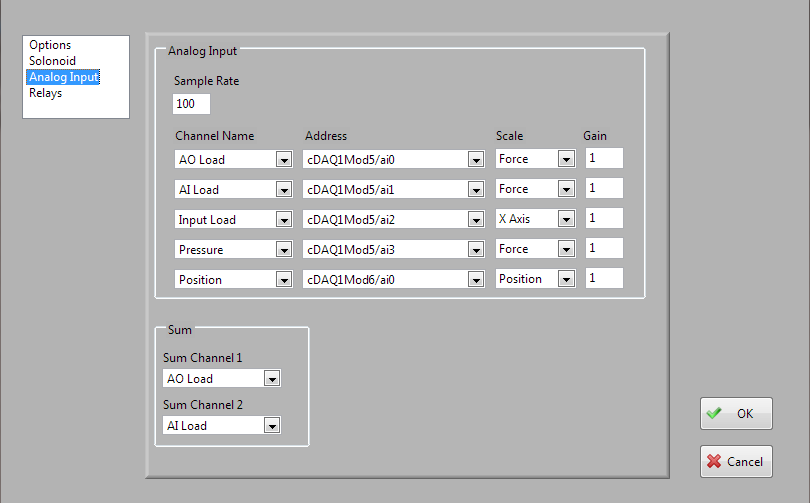

Analog Input

Report

The software saved data as an excel report. The customer had an excel template and the software populated the data into the specified cells. Using this method the customer could change the report layout, edit macros, and adjust calculations.

Results

Let's build an application together. Contact us today

- Learn how we do a project

- Learn about NI Compact DAQ Hardware

- Learn about Data Acquisition

- Learn more about LabVIEW

- Learn about other test systems we have done for Automotive Customers