Automatic Acoustic Calibrator for Hydrophone Testing

Overview

Automatic Acoustic Calibration for Hydrophone testing. A company that develops and manufactures hydrophones needed software to run and acquire data from their acoustic calibrator. A hydrophone is an underwater microphone that detects sound. An acoustic calibrator is a device that is filled with water and contains a speaker which allows the operator to perform testing on the hydrophone. The company needed the software to automatically adjust 2 output waveforms that were connected to 2 speakers and record the hydrophone response over a set frequency range. The software needed to save the hydrophone sensitivity verses frequency and the hydrophone phase verses frequency to an excel file to be analyzed at a later time. The software also needed to be easy to use to reduce training and operating costs.

.jpg&ts=20120620103609&ri=640)

Open-water monitoring using a hydrophone

Solution

The acoustic calibrator used a NI USB data acquisition board to drive 2 speakers and acquire data from up to 8 hydrophone channels. The NI USB data acquisition board was a high sampling rate simultaneous sampling board. The high sampling rate was needed to measure the high frequencies needed to do the testing. Simultaneous sampling was needed to accurately measure phase. Simultaneous sampling is a feature in data acquisition cards where each channel has its own Analog to Digital Converter. This insures all measured channels are captured at the same instance in time.

NI USB Data Acquisition Hardware

Working with the customer we helped developed an algorithm that automatically adjusted phase and amplitude to get a valid measurement from a series of frequencies. The algorithm was very challenging to develop. It was a 2 variable non-linear control problem. We developed prototype software using LabVIEW that allowed the customer to quickly change the algorithm and verify it in the acoustic calibrator. Using this prototype software the customer was able to quickly and confidently develop the complex algorithm needed to control the calibrator.

Features

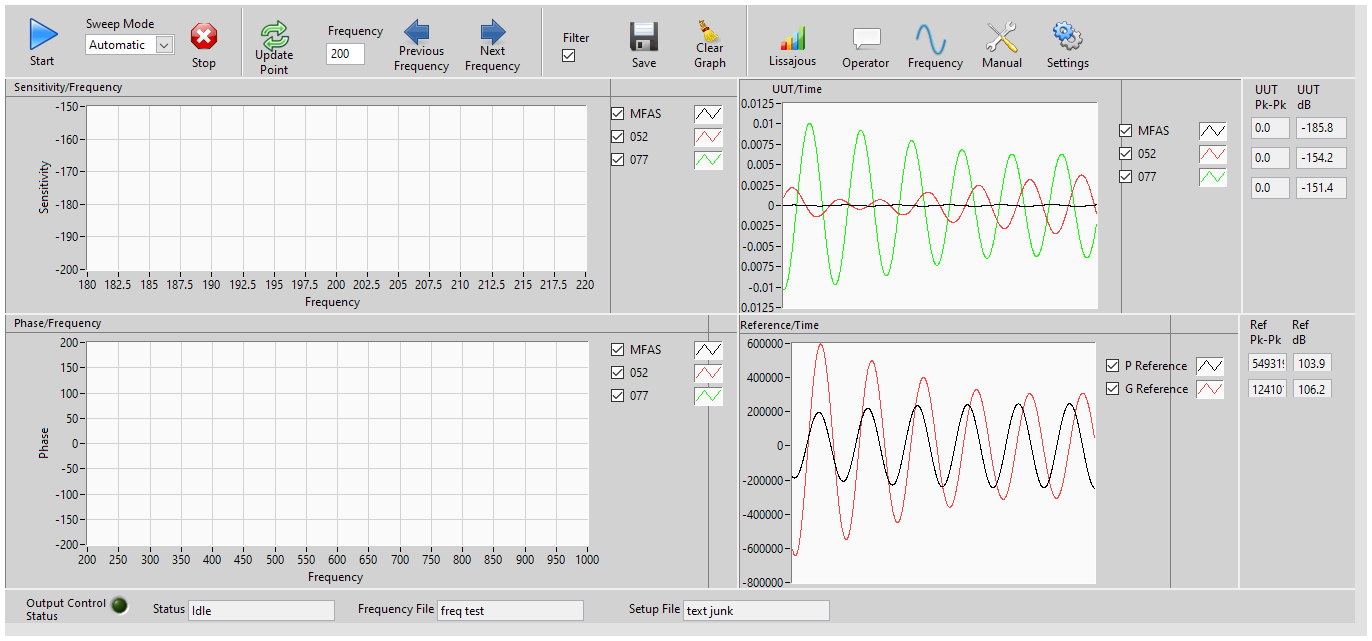

The software automatically stepped through a list of frequencies and measures the sensitivity and phase of the hydrophone. The operator also had the ability to retake a measurement at a defined frequency if the data was suspect. The software then saved that data to a customer defined excel template. The excel template enabled the customer to make modifications to the report without any code changes.

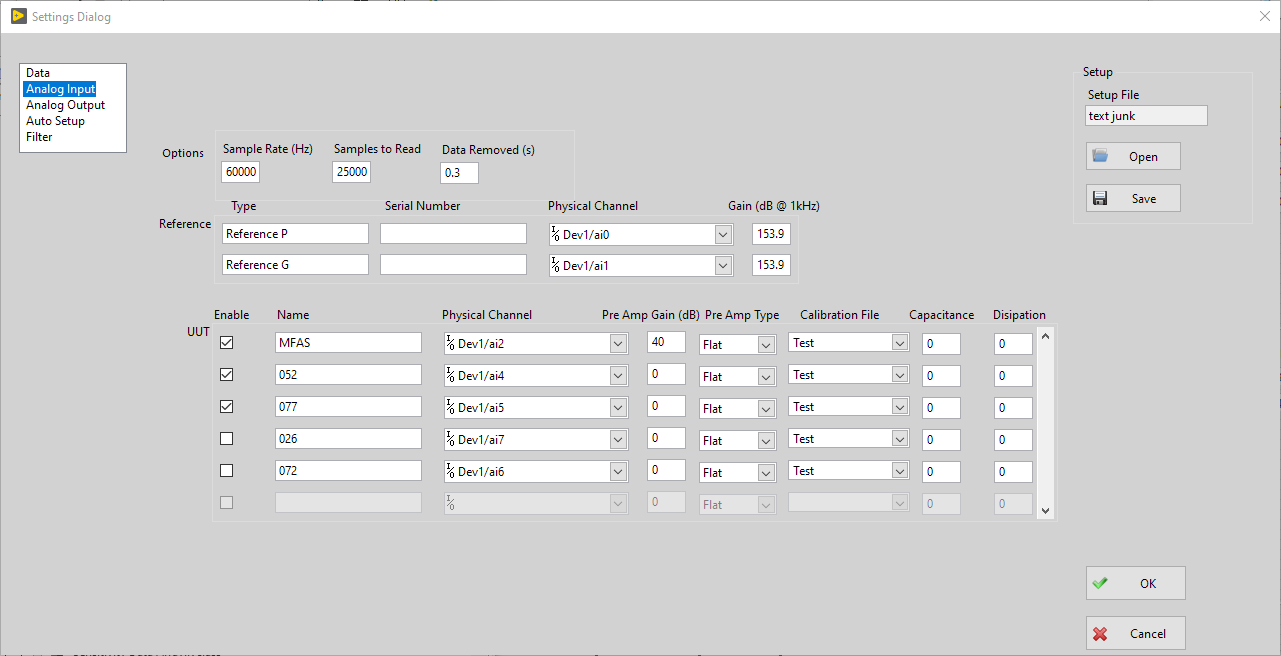

Settings Dialog

The settings dialog allowed the user to adjust software settings. The operator could save and load different setting configurations based on the test being run. Each group of settings had a different screen. This allows for the operator to concentrate on only a group of settings making the user interface easier to navigate.

Settings Dialog

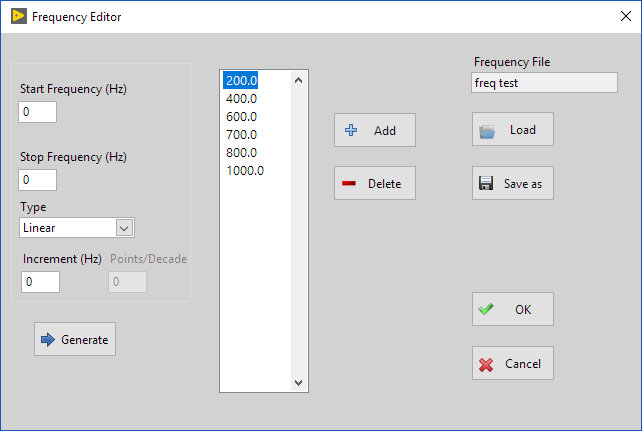

Frequency Editor

The frequency dialog allowed the operator to specify a list of frequencies to test the hydrophone. Frequency lists could be saved and loaded from file. The dialog also had the ability to generate a frequency list, either a linear or logarithmic.

Frequency Editor

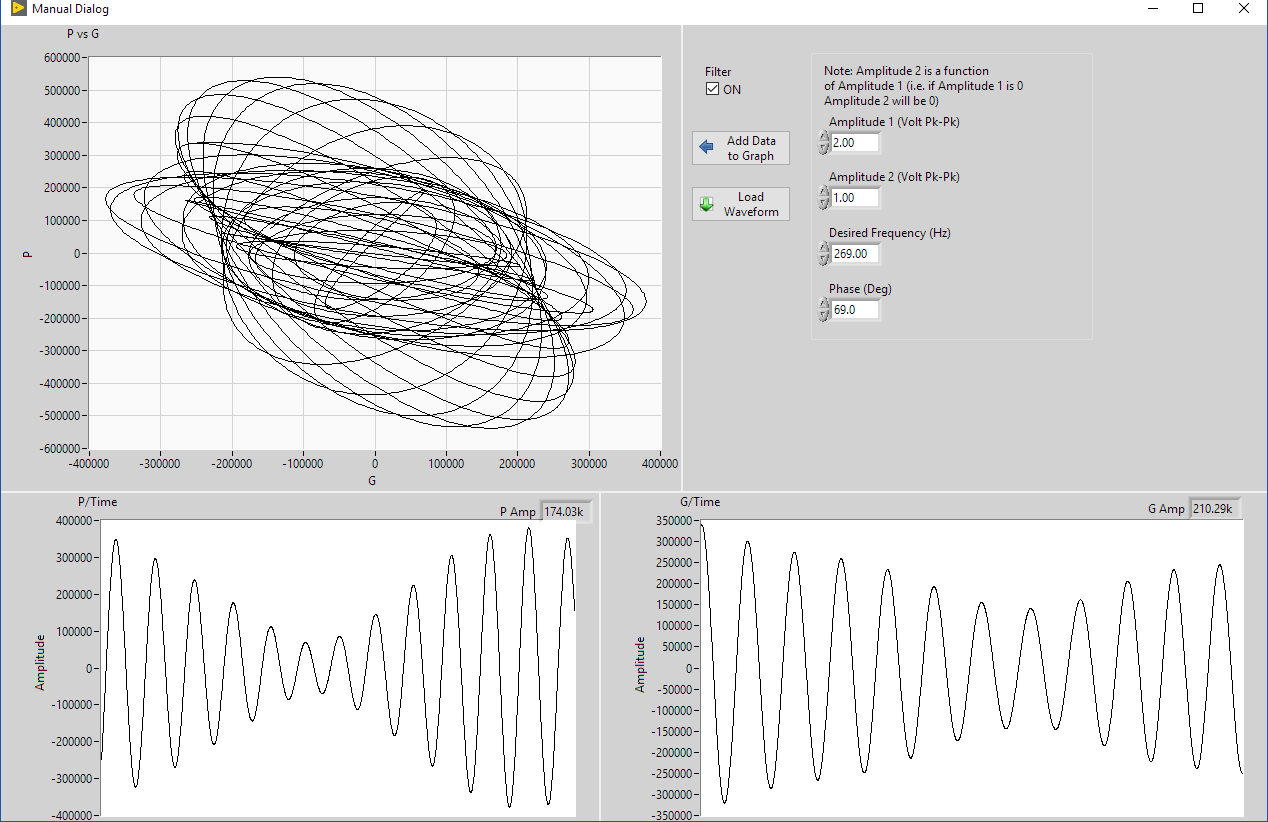

Manual Dialog

The manual dialog allowed the operator to set up the amplitude and phase manually and display the amplitude of measured signals. This was useful if the operator wanted to quickly check the hydrophone at a specific amplitude, frequency, and phase.

Manual Dialog

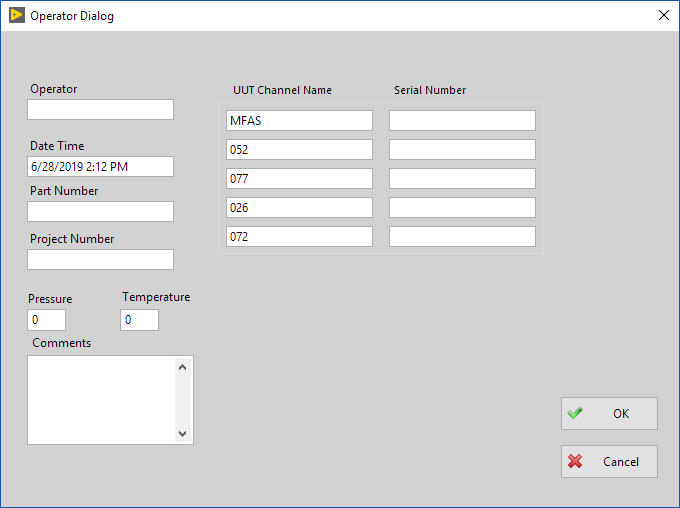

Operator Dialog

The operator dialog allowed for test data to be entered into the excel report.

Operator Dialog

Excel Report

The test data was saved to an excel file. The customer created an excel template that had macros to automatically graph the saved data. The software loaded the excel template and populated the data in the specified fields. Using an excel template allowed the customer to change the excel file without any software code modifications.

Result

The Automatic Acoustic Calibrator for Hydrophone Testing software automated the process for calibrating the customer hydrophones. The ability to automatically step through a list of frequencies saved the customer over 10x of time testing their product. The software was also much easier to use than the previous method of performing calibration. Previously a highly trained operator had to perform the testing. The new software allowed for any operator with minimal training to run the tests.

Automating the test and a very easy to use user interface saved the customer testing and training time. This was an enormous cost savings over the previous method.

Lets build an application together. Contact us Today

- Learn about our project process

- Learn about LabVIEW

- Learn about NI USB Data Acquisition Hardware

- Learn about other test systems we have developed