Automotive Torque Angle Sensor testing using SENT and LabVIEW FPGA

Overview

Automotive Torque Angle Sensor testing using SENT and LabVIEW FPGA. An automotive test lab needed software that communicated with 2 UUTs under tests via SENT. The product was a torque sensor used in automotive applications. The customer needed to command a motor to rotate and then read the angle of the sensor using the SENT protocol. The customer had some existing LabVIEW FPGA code that they wanted integrated to communicate with a windows program that could monitor and send commands to the torque sensor via SENT. The customer also had a motor that needed to be controlled using RS-232 (Serial).

Solution

The Customer had a a FPGA based LabVIEW program that was able to communicate with 1 SENT torque angle sensor. The SENT (Single Edge Nibble Transmission) protocol is a point-to-point scheme for transmitting signal values from a sensor to a controller. It is intended to allow for transmission of high resolution data with a low system cost. Field-programmable gate arrays (FPGAs) are reprogrammable integrated circuits that contain an array of programmable logic blocks. FPGA chip adoption is driven by their flexibility, hardware-timed speed and reliability, and parallelism. The customer also had a Mitsubishi Melservo J3 servo motor and drive that needed to be controlled using RS-232 (Serial). Serial communication transmits data between a computer and a peripheral device, such as a programmable instrument or another computer. Serial communication uses a transmitter to send data one bit at a time over a single communication line to a receiver.

Block Diagram

We had to modify the existing FPGA program to enable 2 torque angle sensors to be monitored instead of one. We also put in the FPGA code the ability to send and receive data to a LabVIEW windows program. The FPGA code read the angular position of the encoder and the angle of the torque angle sensor using the SENT protocol.

We developed a LabVIEW program that resided on a windows PC that functioned as the user interface for the test. The LabVIEW windows program allowed the user to enter test parameters, communicate with the servo motor and the torque angel sensor, and graph and log data to file.

Torque Angle Sensor

Features

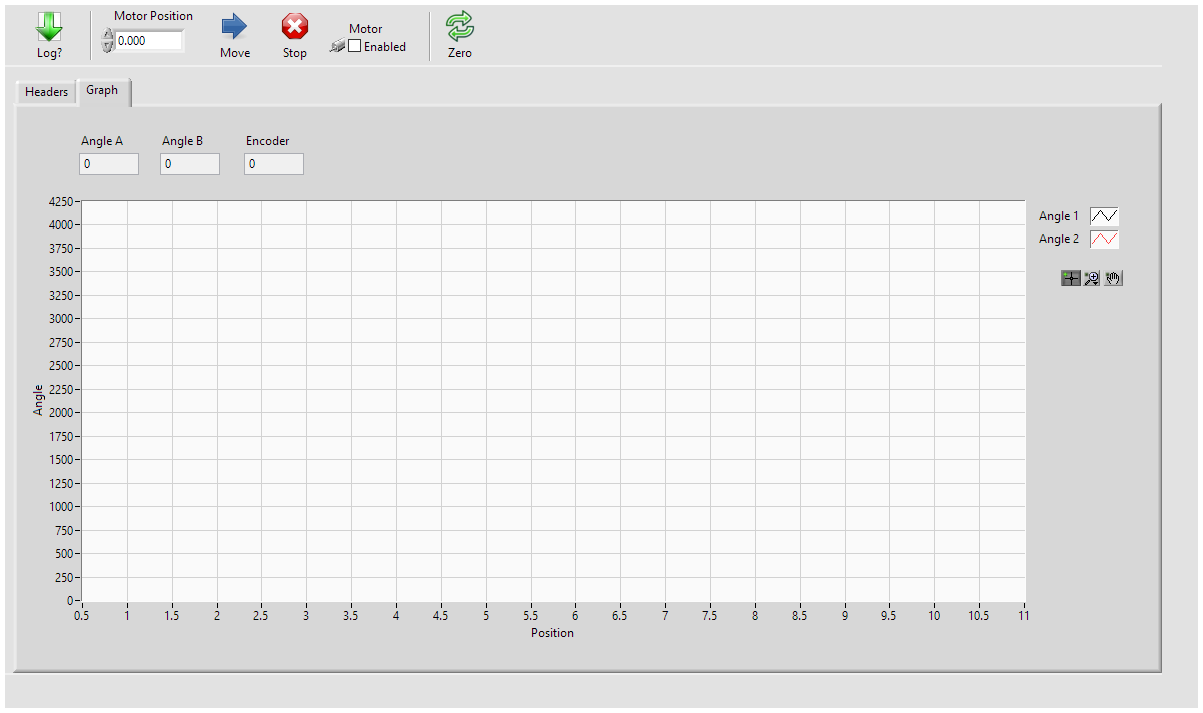

Main Screen

The LabVIEW windows software allowed the user to enter test parameters to the data file. The software logged data from the torque angle sensor and displayed the data in a graph. The user had the ability to specify a angular motor position and send the position command to the servo motor. The software displayed the current values of both angles and the value of the encoder from the torque angle sensor.

Main screen with graph

Main screen with test information

Data File

The data was saved as a comma separated value file (.csv). CSV files are a human readable file format can be read by any analysis program including excel. This made the data file format usable for many years regardless of the data analysis program.

Example of data file in Excel

Result

The automotive torque angle sensor testing using SENT and LabVIEW FPGA enabled the customer to test the torque angle sensor efficiently and reliably. Any operator could run the test and get the required data freeing up engineering resources. The customer used the data captured by the test to improve the design and quality of their product. LabVIEW FPGA was a good choice to do the SENT communication because of its speed and parallelism.