Automotive Console Cycle Tester using CAN

Overview

Automotive Console Cycle Tester using CAN. An independent testing lab needed to test an automotive console. An automotive console is a device in an automobile that controls the options in a car. For example the heating and air conditioning and the radio. The customer wanted to test up to 10 consoles simultaneously. The consoles also could be different models of consoles. They needed the software to send and receive CAN messages to the console and do cycle testing. Cycle testing is a type of test that exercises the part for a defined number of cycles. For example sending a message to turn the radio on and off. The test also needed to allow the user to use a control on the software user interface and send that command via CAN to the device under test.

Solution

We developed a LabVIEW application to test the console using a NI CAN USB interface. A Controller Area Network (CAN bus) is a robust vehicle bus standard designed to allow microcontrollers and devices to communicate with each other's applications without a host computer. It is a message-based protocol, designed originally for multiplex electrical wiring within automobiles to save on copper, but it can also be used in many other contexts.

We used a NI USB 8473 CAN Interface device to connect the PC to the consoles.

NI 8473 CAN Interface

The software allowed the user to set parameters for each step of the profile and set the number of cycles to run. The software monitored the current state of the console and displayed the state on the user interface. The user was also able to interact with the user interface to send CAN messages to the console. The software was able to test up to 10 consoles simultaneously, and each station could be a different model console. This allowed the customer to greatly speed up console testing and gave them the flexibility to test different model consoles and add consoles in the future.

Features

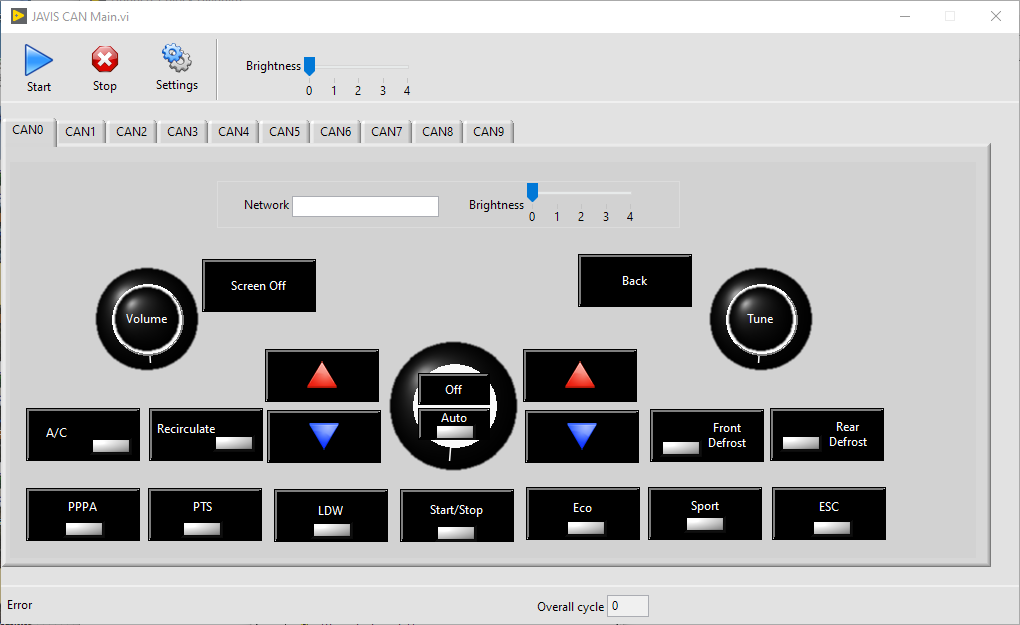

Main Screen

The console tester software allowed the user to manage, control, and monitor cycle testing of each console. From the main screen the user could see the current state of each console under test, the current status of the cycle test, and had the ability to modify controls on the user interface and send the CAN commands to the console.

Settings Screen

The settings screen allowed the user to set the CAN address and station name for each station. The settings screen also had the capability to define the steps of the profile for the cycle test.

CAN Options Settings Dialog

Profile Options Settings Dialog

Result

The Automotive Console Cycle Tester using CAN allowed the customer to automate and increase the speed of the console cycle test. The software was able to test 10 consoles at the same time. This was an enormous time improvement over the previous test method the customer was using. The software was also able to automate the cycle testing freeing up technician resources. We used a standard off the shelf NI CAN interface module that easily allowed the PC to communicate the console under test. The system we developed improved the test time 10 times and allowed for automated cycle testing of the console.

Let's build an application together. Contact us today

- Learn how we do a project

- Learn more about CAN

- Learn more about LabVIEW

- Learn about other test systems we have done for Automotive Customers