Battery Energy Test for Electric Vehicles

Overview

An automotive customer that develops batteries for electric vehicles needed a custom program to monitor and control an energy test. The energy test consisted of 20 electrical loads connected to 20 battery cells that were controlled with a digital output. Each cell needed be discharged until the cell reaches a user specified level. The battery voltage needed to be monitored and saved to an excel file. The excel file needed to be a template that contained a user defined macro for data analysis.

Solution

We developed this system using LabVIEW and custom circuits boards designed by the customer. A simple user interface was developed along with an installer to make distributing this application to multiple targets very simple.

Communication to the custom circuit board was done with RS-232. RS-232 type of serial communication used for transmission of data normally in medium distances. LabVIEW was a great choice because of its native serial communication libraries.

Custom Circuit Board

Features

Main

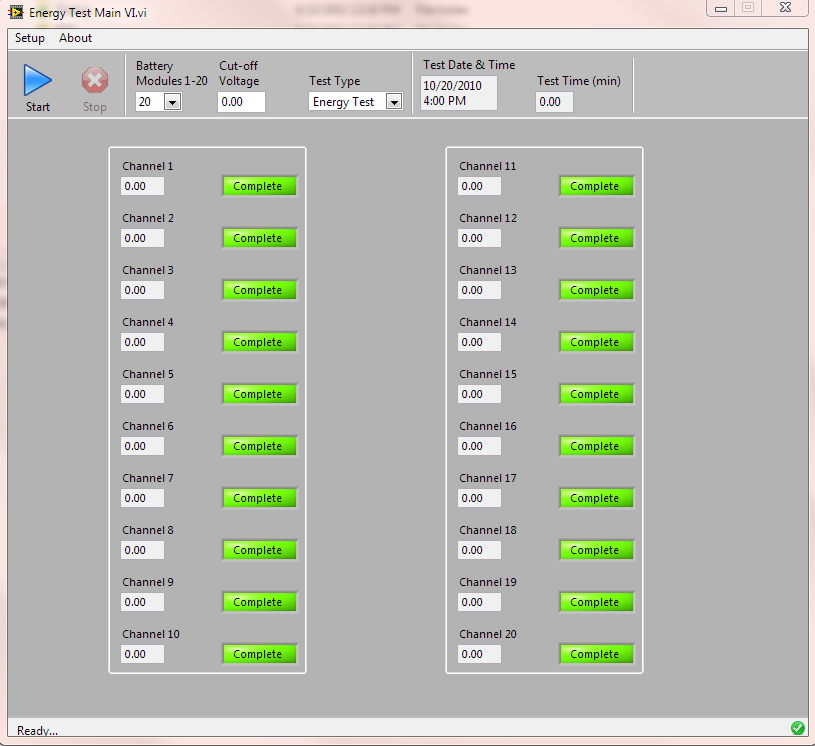

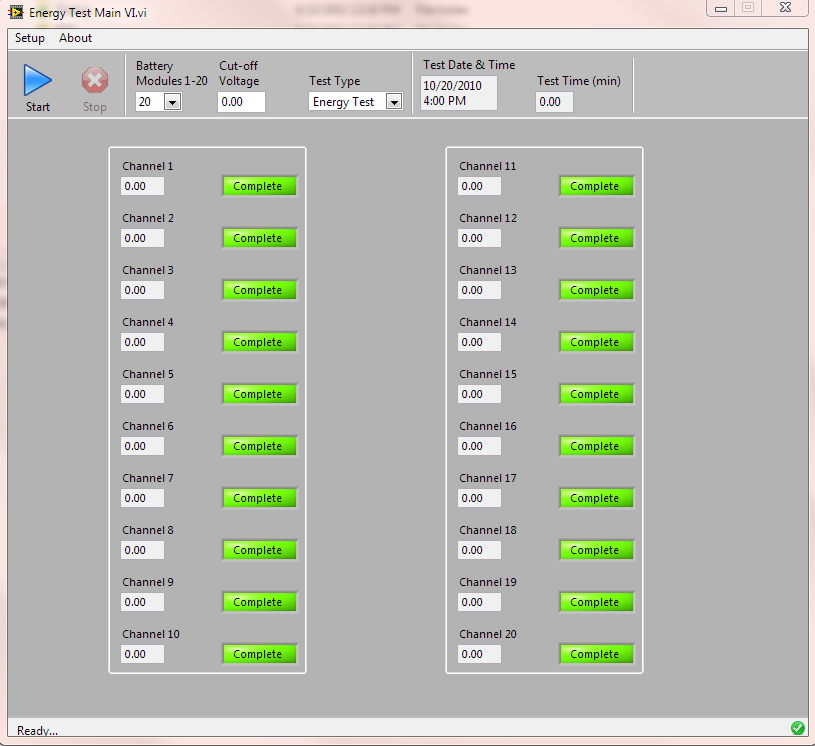

The main screen allowed the user to select the number of batteries to test. The test could test up to 20 batteries. The user could start and stop the test and enter the cutoff voltage for the test. Live numeric indicators of the battery voltages were displayed along with the status of each test.

Setup

The setup dialog allowed the user to set up test parameters. The dialog was password protected to prevent unauthorized access.

Password Protected Test setup screen

Report

Data was saved into a customer supplied Excel template. The customer could modify the template and macros without any code changes.

Excel report

Results

The battery energy test for electric vehicles allowed the customer to easily and effectively test the batteries. The custom hardware we had developed lowered the hardware costs and the customer was able to build many testers at a lower cost compared with off the shelf data acquisition hardware.

Let's build an application together. Contact us today