End of Line Functional Motor Tester using LabVIEW and PXI

Overview

End of Line Functional Motor Tester using LabVIEW and PXI. A Motor manufacturer needed a custom functional tester to test their product. A functional tester is a test that verifies the product works as designed before being shipped to the customer. They needed software that was easy to use and the ability to add or remove tests based on the product they were testing. The motor test had different signal types that needed to be measured such as an encoder, resistance, inductance, and analog inputs. The test also needed to communicate to the motor to send and receive commands and motor status. They also wanted a reporting feature that showed the testing data on the product over time. A simple and easy to use user interface was needed to reduce training costs.

Solution

We developed a custom LabVIEW application with NI PXI hardware that tested the motors. The NI PXI platform is a high performance modular hardware platform. We were able to get a PXI module for each of the different measurement types and communication protocol. NI had a very high performance Digital Multimeter that very accurately measured resistance and inductance. This met the customer's high standards they had for testing their product. We also used a multiplexer to switch between channels to be measured by the DMM. This greatly lowered the hardware cost because we could use 1 DMM for the entire test system.

The user interface was very easy to use. It indicated to the user weather test passed or failed and what part of the test passed or failed. We also included tools in the software for the engineer managing the test to use. This made setting up a test easy and intuitive. We also designed a reporting feature that allowed the customer to view results of the previous tests run. This provided necessary quality control data that could be fed back to the design team.

Example of a PXI System

Example of a Multiplexer Circuit

Features

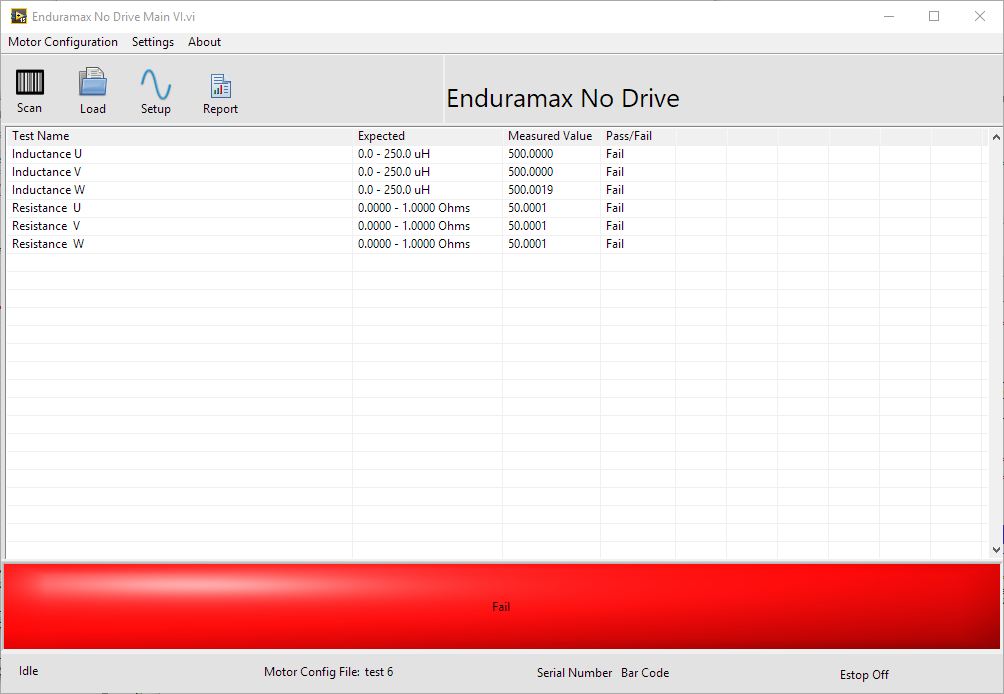

Main Screen

The End of Line tester was very easy to use and intuitive for the user. All the tests were listed in a table on the front panel with the acceptable range and the measured result. We also included if each test passed or failed based on the measured value. If all the tests passed we had a large green indicator on the bottom that indicated a successful test. If any test failed the indicator on the bottom would be read and the user could see what test failed from the table.

We also included program status along the bottom of the user interface. The user could easily see the current state of the test software, the loaded configuration file, the serial number of the product, and whether the E-stop was on or off.

Setup

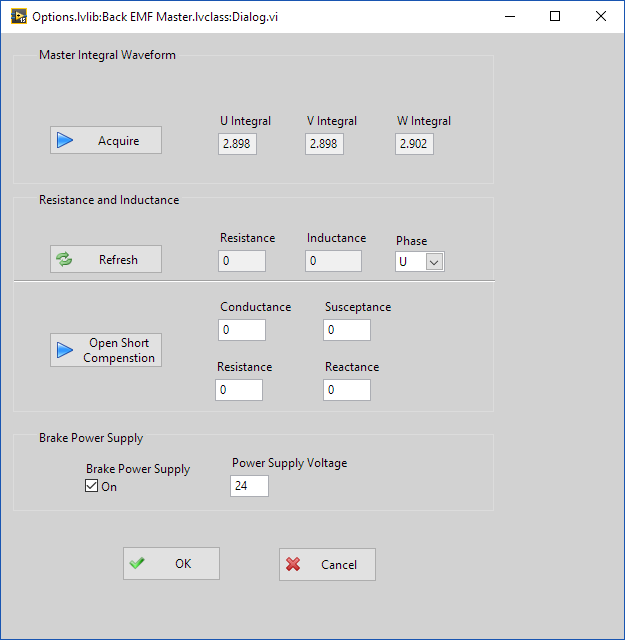

We developed a setup screen that the operator could easily set up the tester. A master part with known good values was set in the test fixture and then the the operator could run the different setup routines. The setup screen was very easy to use and didn't require much operator training.

Setup Dialog

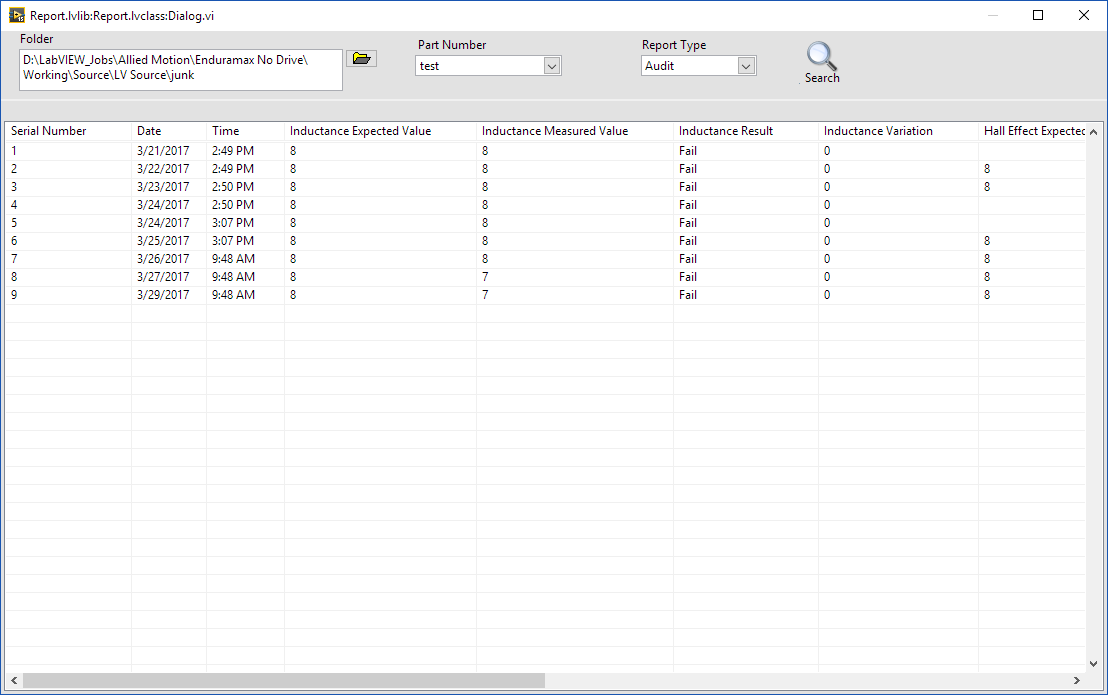

Report

The report dialog allowed the operator or engineer to view test results of different motors over time. The user could search by part number and by report type. The operator could see the results of each test and the date it was tested. This was very valuable data the customer could use to improve their quality control.

Report Dialog

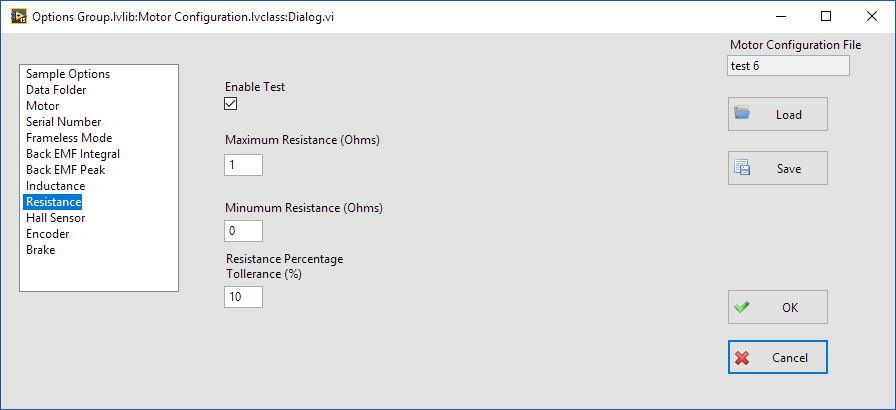

Motor Configuration

The motor configuration screen contained a list of tests to run on the motor. The engineer could select whether to run the test and set the test parameters. The engineer could save the configuration to disk to be loaded at a later time. When a set of motors needed to be tested all the operator had to do was load the corresponding motor configuration file.

Motor configuration screen

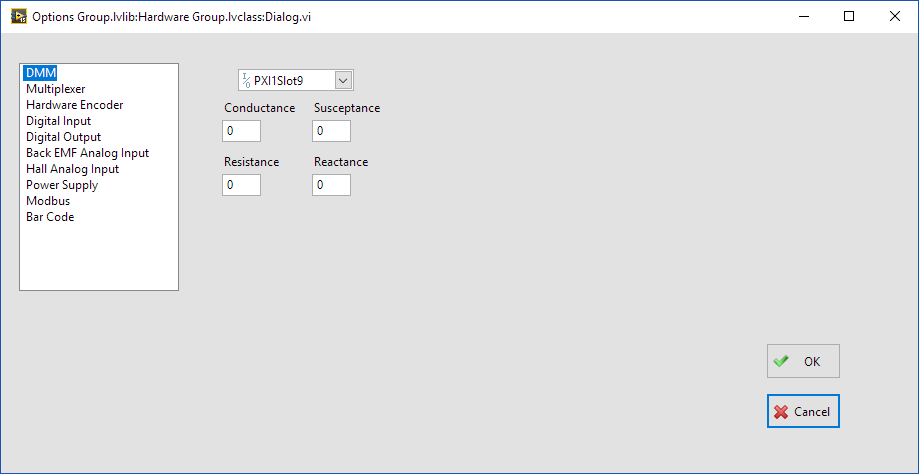

Settings

The settings dialog allowed the engineer to set the hardware settings for the tester. Settings like channel address, multiplexer settings, and channel gain were included. The settings dialog was password to prevent operators from changing the settings.

Settings Dialog

Result

The End of Line Functional Motor Tester using LabVIEW and PXI was able to easily test the customer's many configurations of motors easily. The NI PXI hardware allowed the customer to use standard off the shelf hardware to perform the needed tests eliminating the need to develop custom hardware. The PXI platform was also able to accommodate all the signal types the customer needed to measure.

The tester was able to do all the tests automatically where previously an engineer had to do the tests manually. This was a significant savings in test time. The ease of use of the software allowed for any operator to run the software. This freed up engineering resources to make improvements to the motor design and manufacturing. The software also saved all the test results to be used for quality control. Previously all the test result data was written down if at all by hand. This allowed the customer to figure out what was failing on the motors and the frequency of failure.

Let's build an application together. Contact us today

- Learn how we do a project

- Learn about NI PXI Hardware

- Learn about NI Multiplexers

- Learn more about LabVIEW

- Learn about other test systems we have done for Industrial and Commercial Customers