Drop Impact Tester Using Control Techniques Unidrive Motor Drive and LabVIEW

Overview

Drop Impact Tester Using Control Techniques Unidrive Motor Drive and LabVIEW. A company that designs and manufactures office furniture needed to upgrade the user interface to their drop impact test machine. A drop impact tester is a test that drops a weight on a product for a defined number of cycles. The previous user interface was developed in a software package that wasn't supported anymore. The previous user interface was also not intuitive to use by the operator. They needed the user interface to connect to the drive via Modbus. The customer also had existing motor drive and controller hardware and wanted to reuse it.

Solution

The customer choose LabVIEW as the user interface because of its wide use, powerful user interface library, and LabVIEW's ability to connect to hardware. LabVIEW was a great choice because it had an available Modbus library allowing the customer to reuse their current hardware. Modbus is a data communications protocol for use with programmable logic controllers (PLCs). Modbus has become a standard communication protocol and is now a commonly available means of connecting industrial electronic devices.

We redesigned the user interface to be more intuitive for the operators. This lowered training costs and reduced operator mistakes when setting up and running a test.

Features

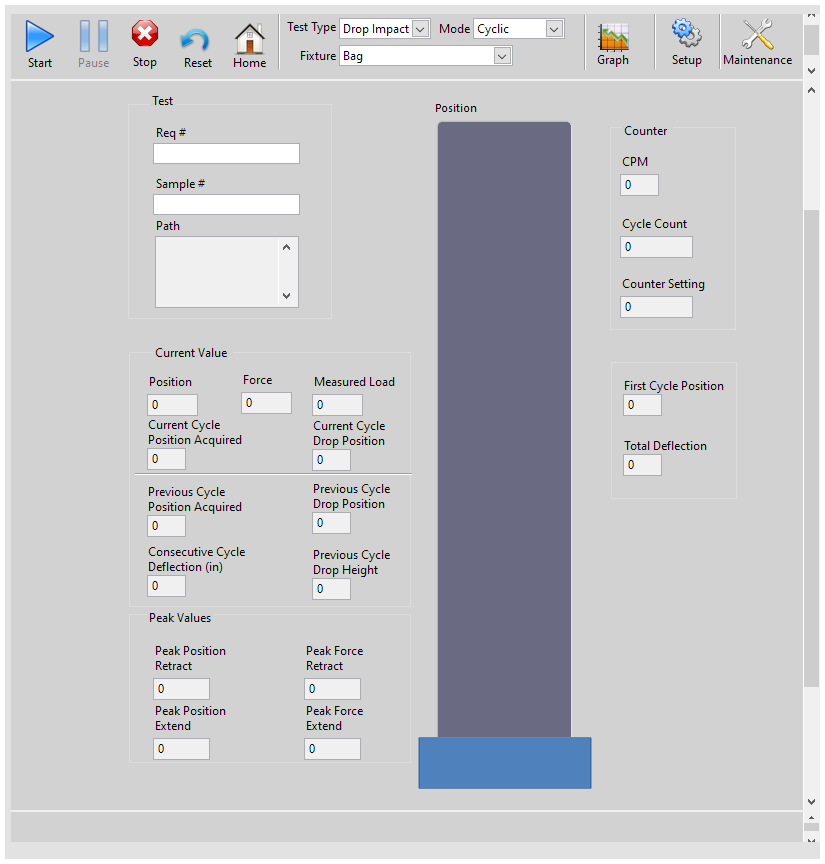

Main Screen

From the main screen the operator could start, pause and stop a drop impact test and enter test settings. The operator could also set the motor home position and send a reset command to the drive. The operator could also at a glance observe the current status of the test.

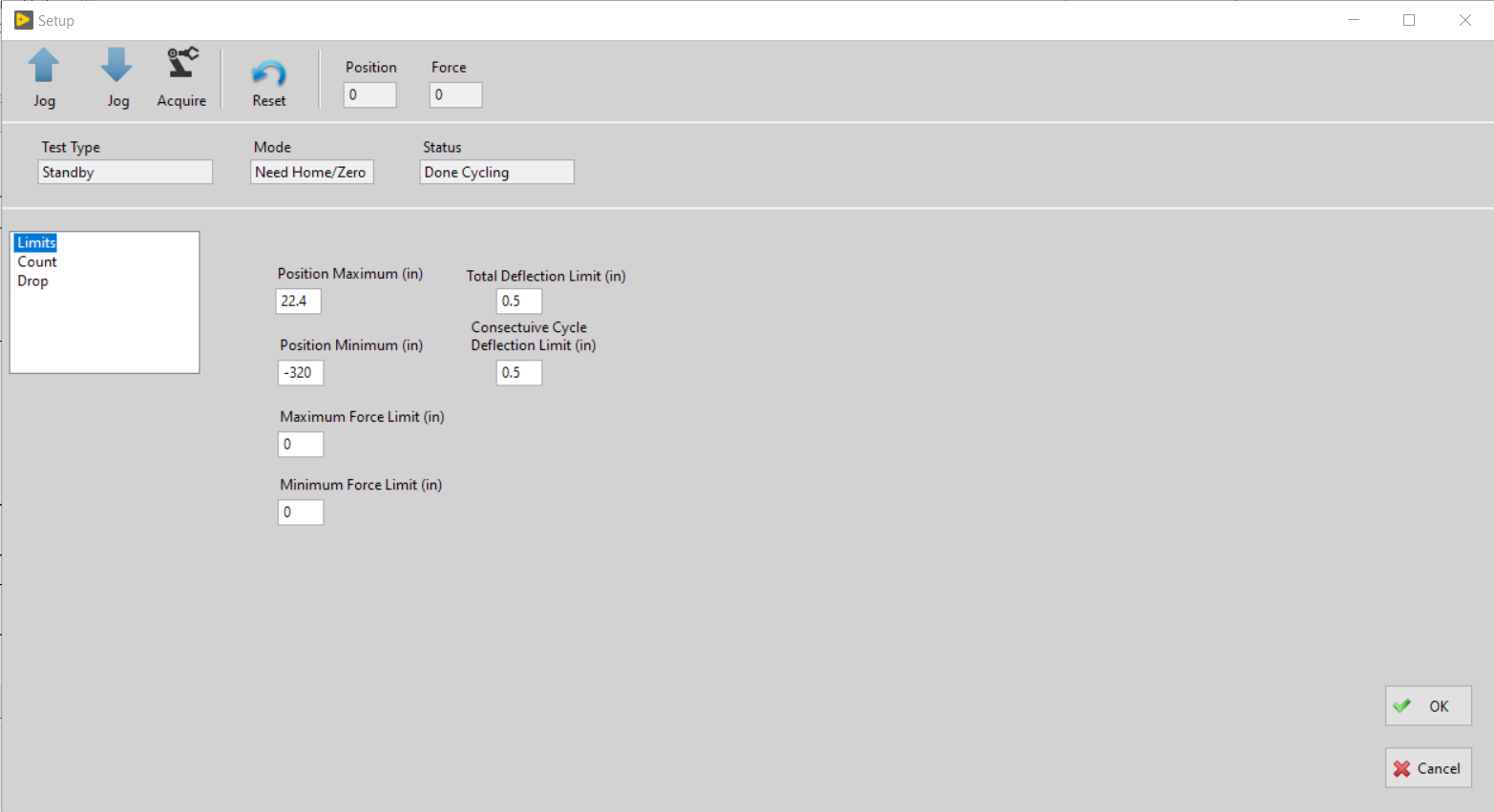

Setup

The setup screen allowed the user to set up the software. The user could also jog the motor and see the current status of the program that was running on the motor drive.

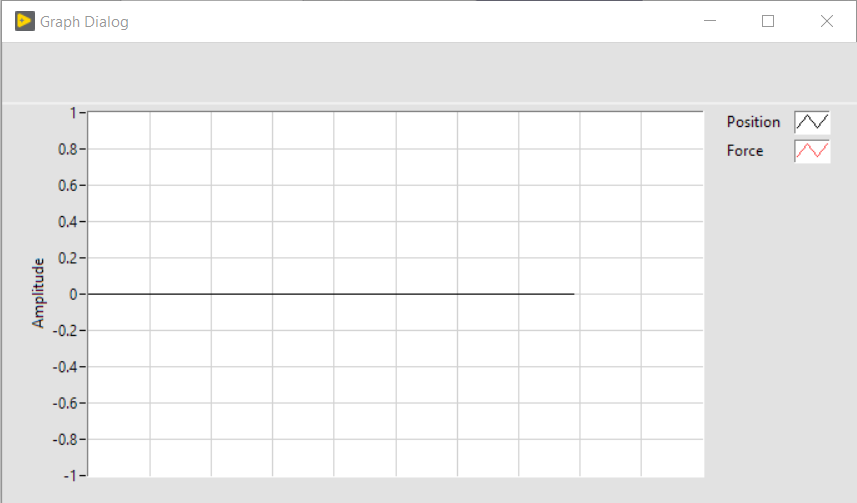

Graph

The graph dialog was a floating dialog that allowed the user to view test parameters over time. The dialog was floating so the operator could access the rest of the test screens with the graph dialog running.

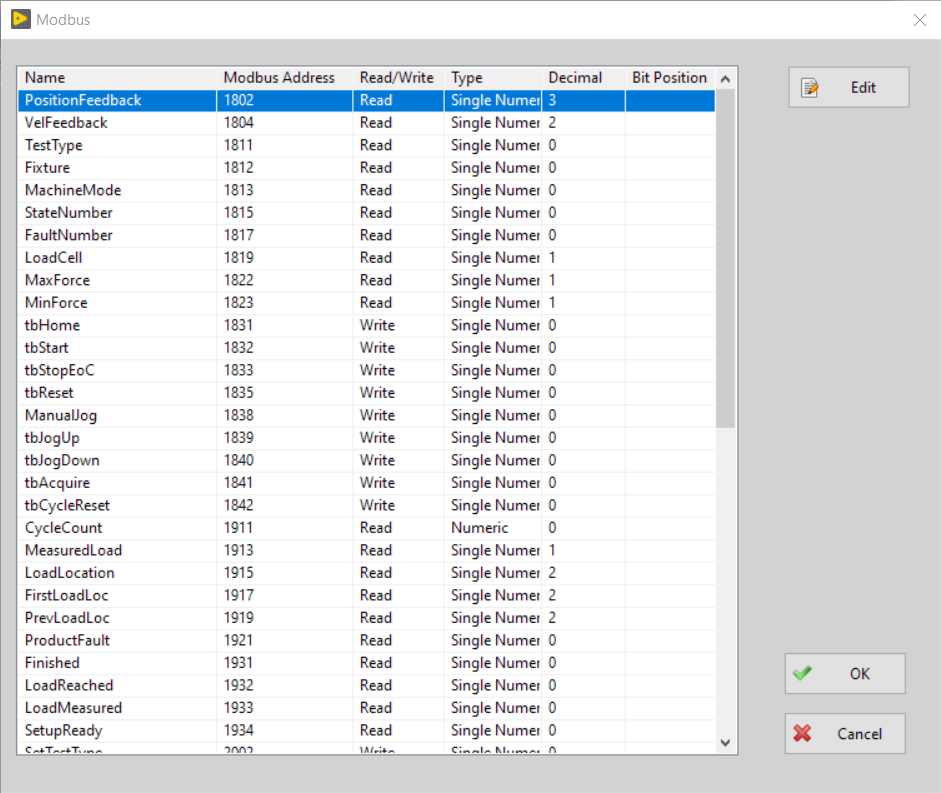

Modbus Address Editor

The Modbus Address Editor allowed the user to manage the Modbus address for the program.

Report File

The data gathered from the test was saved to a .csv (comma separated value) file. CSV files are useful because they are human readable and can be opened in any data analysis software i.e. excel.

Result

Drop Impact Tester Using Control Techniques Unidrive Motor Drive and LabVIEW allowed the customer to make changes to the user interface software. The user interface software the customer had was discontinued and the customer could not make changes or upgrades. Switching to LabVIEW allowed the customer to have maintainable software for many years. The upgraded user interface design lowered the amount of operator mistakes when setting up a test and made observing the current test data much easier. The software was also distributed as an executable. LabVIEW executables do not need a runtime license from NI so the customer could put the software on many machines without paying additional licensing costs. The ability of LabVIEW to communicate with the customers existing hardware saved them enormous amount of money in hardware costs. We also designed the software to be flexible so if in the future the customer wants to change hardware they would be able to do so.

Lets build an application together. Contact us Today

- Learn about our project process

- Learn about LabVIEW

- Learn about Control Techniques Unidrive motor drives

- Learn about Modbus

- Learn about other test systems we have done for Industrial and Commercial Customers