Bed of Nails Tester for PCB using PXI and LabVIEW

Overview

Bed of Nails Tester for PCB (Printed Circuit Board) using PXI and LabVIEW. An electronics manufacturing company needed a bed of nails functional tester to test their PCB product. The product was a radio that was used by emergency responders. A bed of nails tester is a test that has pins that connects to various test points on the circuit board. The circuit board needed to be powered on and the various test points needed to be measured to verify the the correct signal was present at each test point. They also needed the software to prompt the user to operate buttons on the PCB and verify the correct response i.e. an LED being on. The test was also changing and the system needed to have the ability to easily modify tests or add tests at a later time.

Example of bed of nails tester in contact with a circuit board.

Solution

We developed custom LabVIEW software that used NI PXI hardware. The NI PXI platform is a high performance modular hardware platform. The PCB had multiple signal types and a high number of signals that needed to be measured. We used a multiplexer, which is a device that allows you to route signals from the PCB to the required module on the PXI system. Using this approach we can greatly lower the number of modules needed because we can switch to different test points instead of having a dedicated channel for each test point. This method is also highly flexible because adding a new test point is just adding a new channel map in the multiplexer.

Example of a Multiplexer Circuit

Example of a PXI System

Features

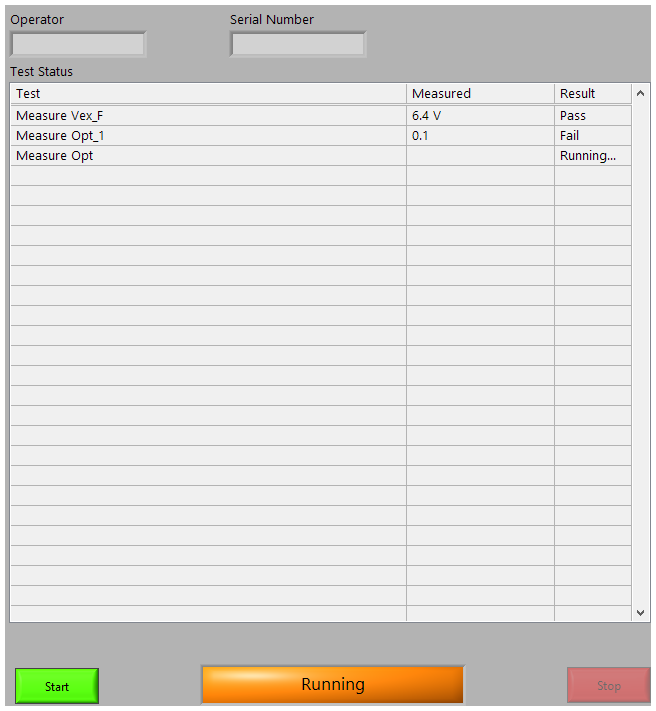

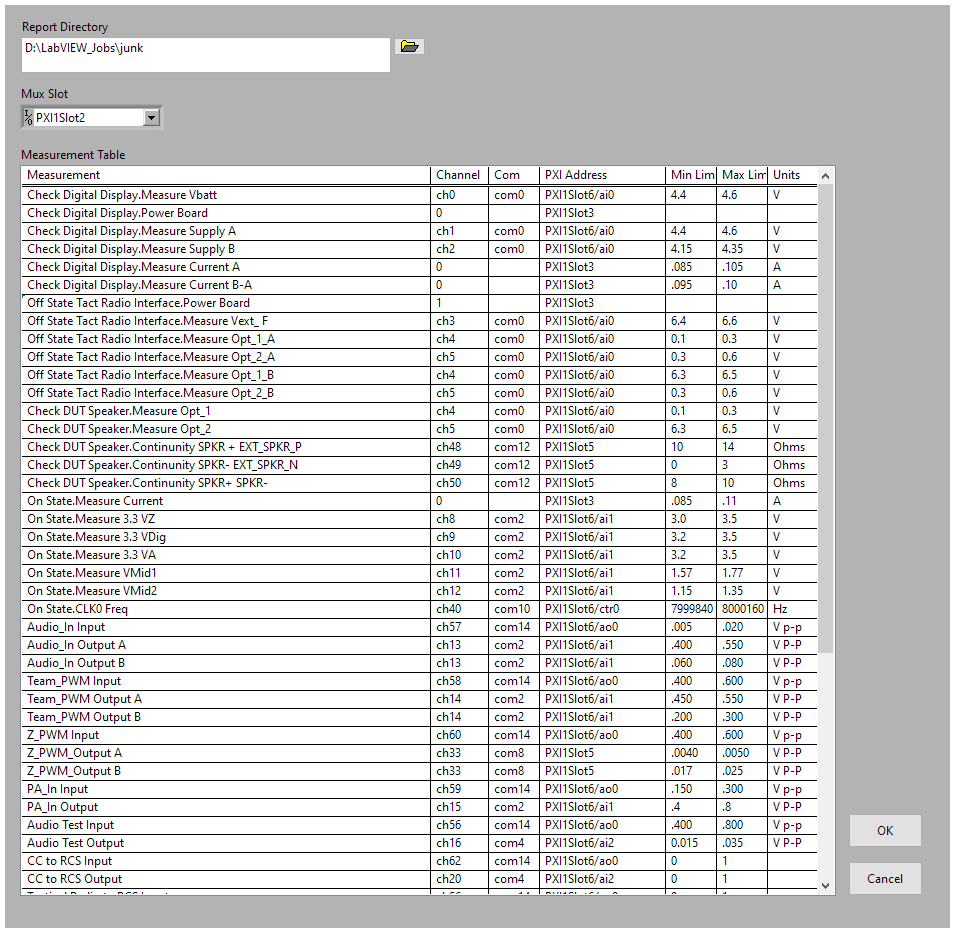

The functional test contained over 50 individual tests. The engineer had the ability to specify high and low limits for each test and the multiplexer switching and the PXI module used to measure the test point.

We designed the user interface with minimal amount of controls so operator training was minimal. All data was saved in an XML format to allow data to be imported to a data base at a later time or for easy analysis in Microsoft Excel.

A feature that allowed an engineer to set pass/fail criteria was also included in the software. This allowed the customer to change test pass/fail criteria based on product design changes without making changes to the source code.

Advanced Options screen with each test with Multiplexer map, PXI channel, and Limits

Result

This functional test made testing the customer circuit board very fast and easy. It allowed the customer to incorporate new tests that needed to be performed due to a changing design. It was also easy for operators to use and captured all relevant test data.

The functional test allowed the manufacturer to have an operator perform the test instead of an engineer manually checking all the test points with a DMM or other piece of test equipment. This allowed the test to be performed in a matter of minutes instead of hours saving an enormous amount of time and money. Also test data was automatically saved in a human readable format so the manufacturing team could see what tests were failing, and how they were failing. The manufacturing team was then able to feed that data back to the design team to make a higher quality product.

As a result of AST developing the Bed of Nails Tester for PCB using PXI and LabVIEW the customer was able to quickly functionally test their product and generate data they could use to improve their design.

Let's build an application together. Contact us today

- Learn how we do a project

- Learn about NI PXI Hardware

- Learn about NI Multiplexers

- Learn more about LabVIEW

- Learn about other test systems we have done for Industrial and Commercial Customers