Oil and Gas Valve Test Using LabVIEW and CompactDAQ

Overview

Oil and Gas Valve Test Using LabVIEW and CompactDAQ. An oil and gas valve manufacturing company needed custom software to control and monitor their flow test stand. They needed software to monitor pressure, position, velocity, and temperature. The customer also needed the software to actuate the valves to control the stand. Data acquired from the stand needed to be saved in an excel format.

Solution

We developed a custom LabVIEW program with NI CompactDAQ hardware to facilitate their needs. CompactDAQ was chosen because it could measure and output multiple types of signals. The software contained a table that displayed all the measured values in real time. We also developed a simple user interface that allowed the operators to simply control and monitor the measurements of interest.

CompactDAQ Chassis and Modules

The software supported 2 different test stands. We designed the software to use a configuration file to determine what test stand the software was installed on. This allowed for stand dependent features to be only enabled for the appropriate stand.

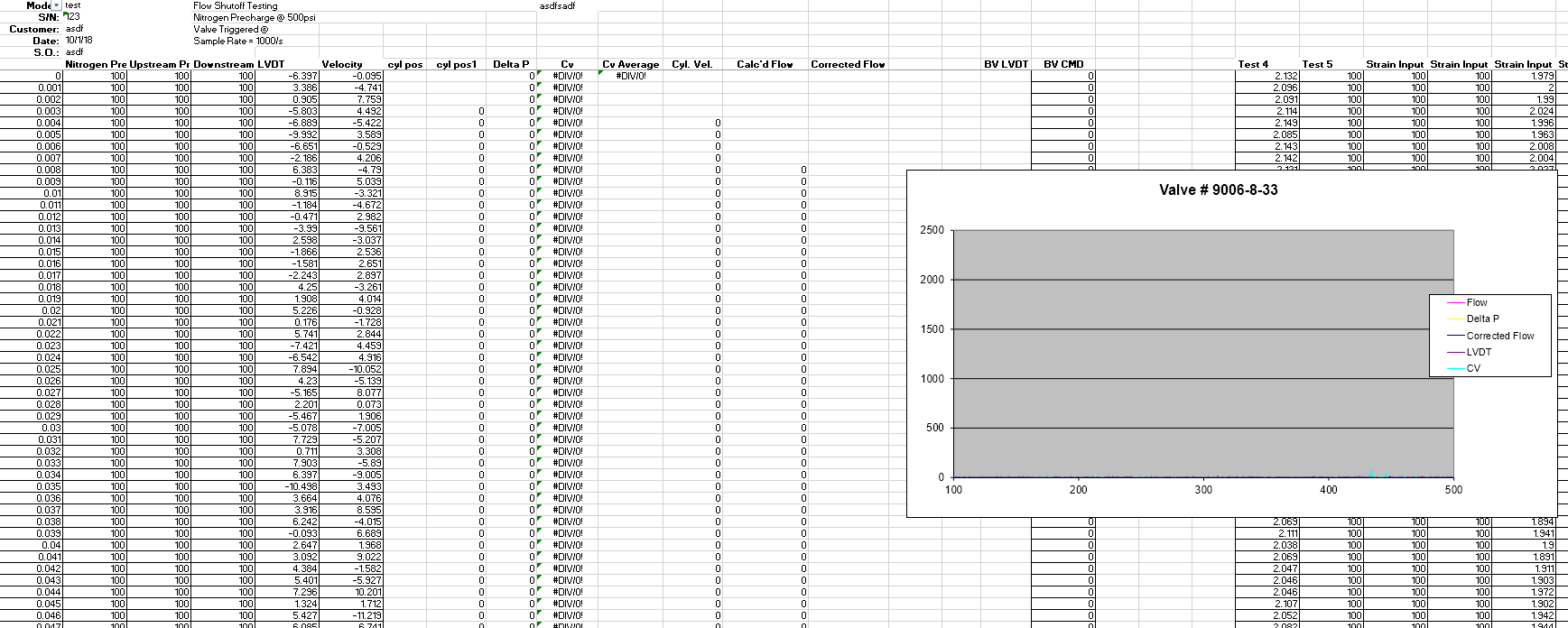

The acquired data was populated into a customer defined excel template. This allowed the customer to change how the data was analyzed and displayed without making software code changes.

Features

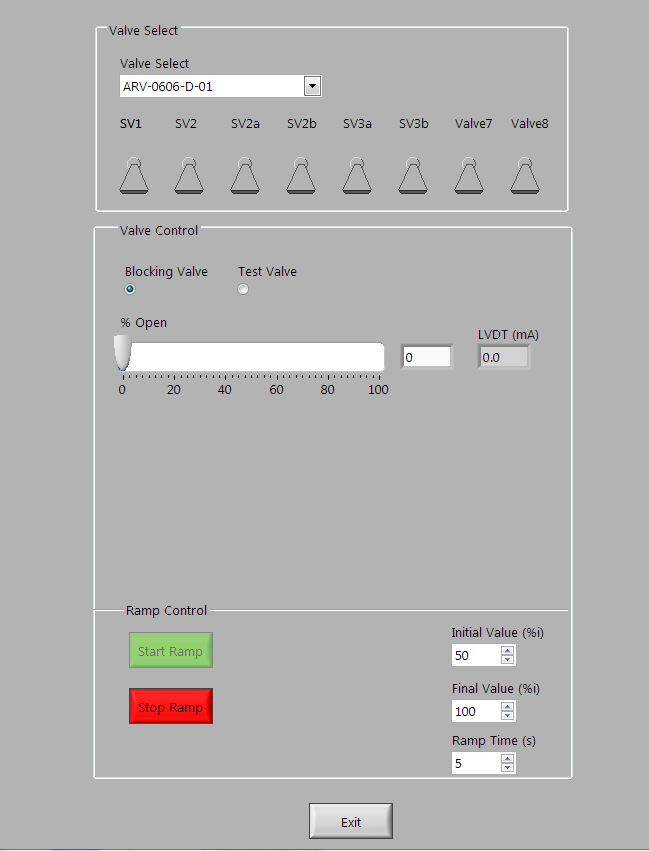

Manual Control Screen

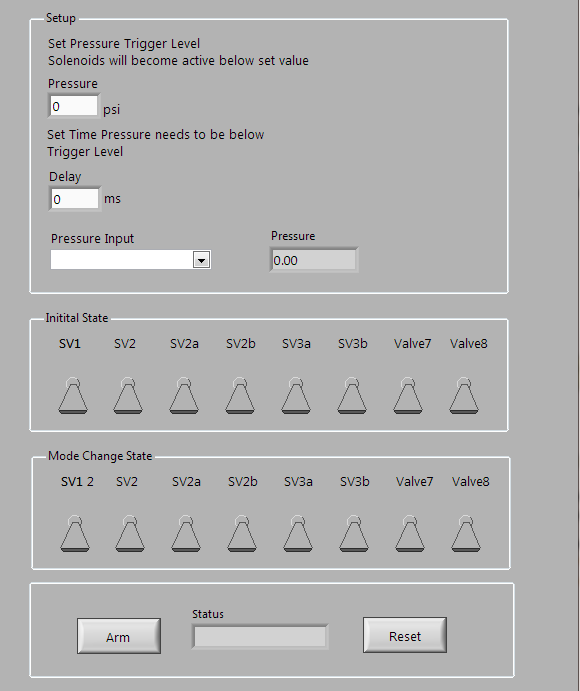

Automatic Valve Control Screen

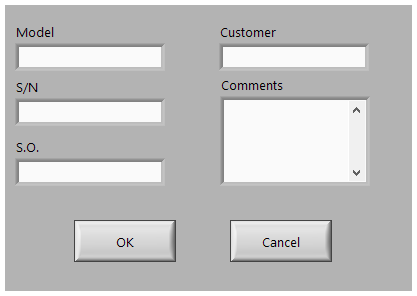

Report Header Dialog

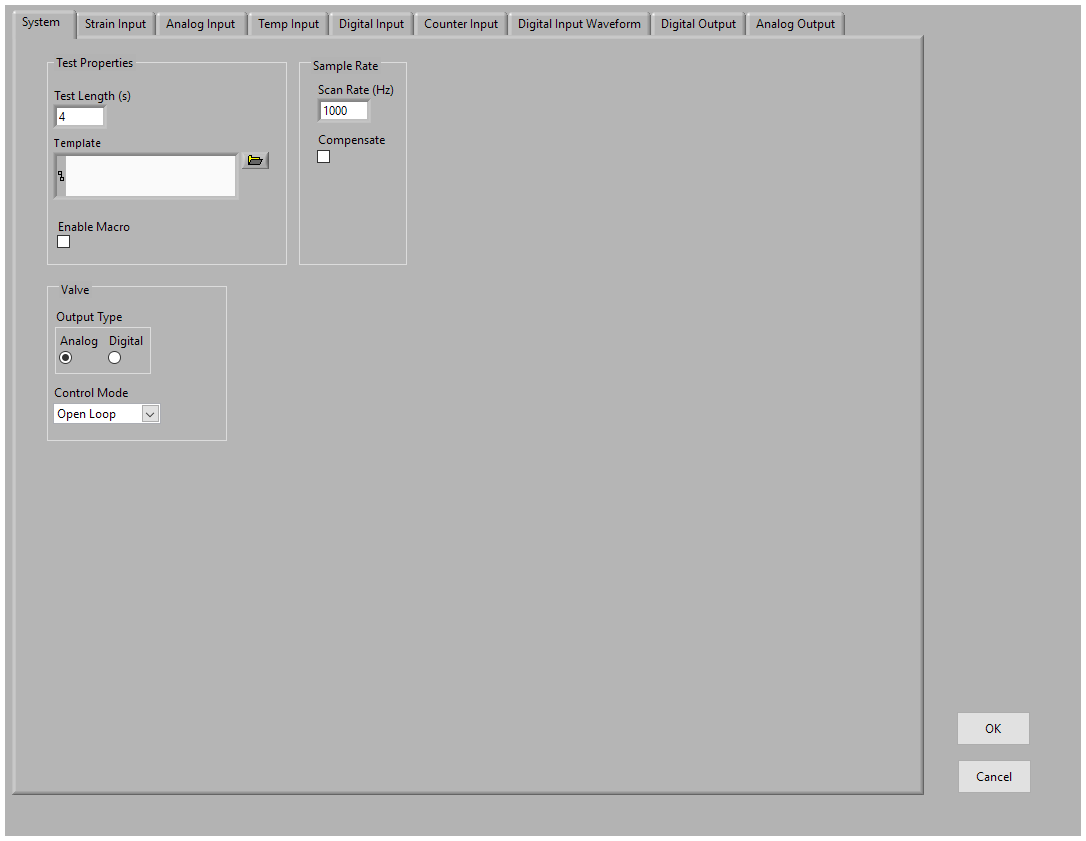

Advanced Options

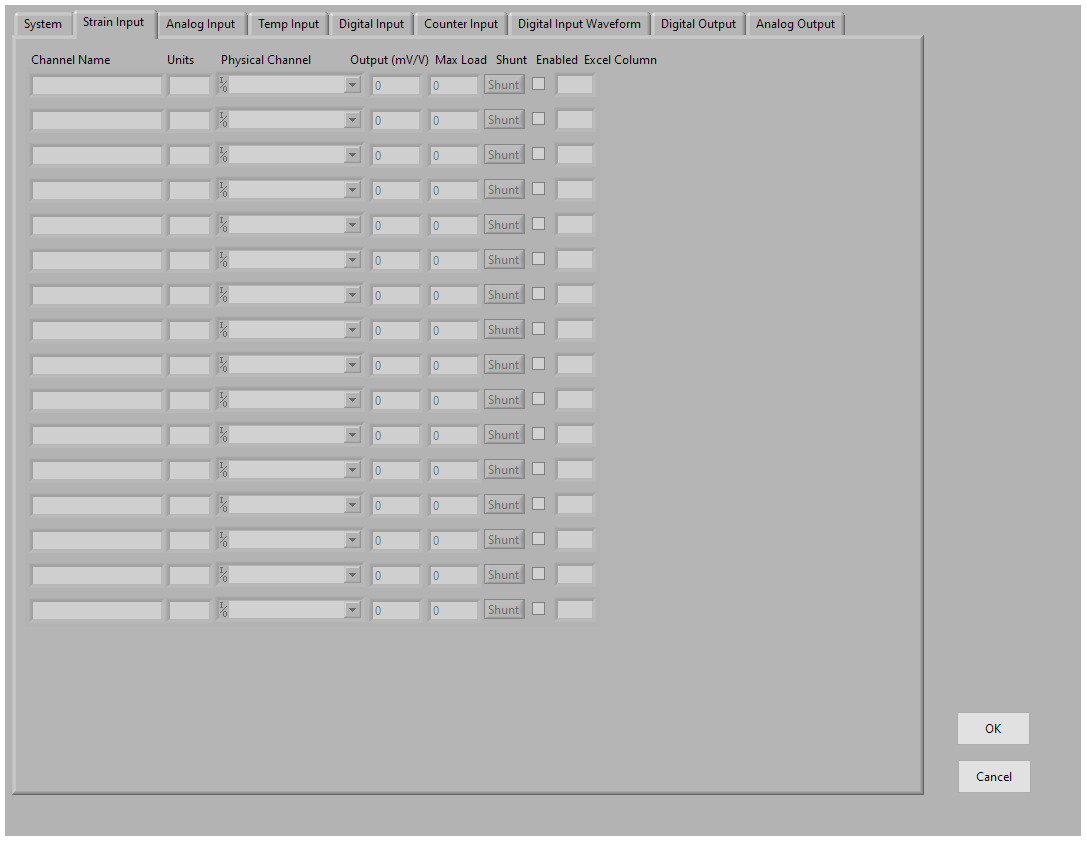

Advanced Options hardware Setup

Report

Result

Let's build an application together. Contact us today

- Learn how we do a project

- Learn more about Data Acquisition

- Learn about NI CompactDAQ Hardware

- Learn more about LabVIEW

- Learn about other test systems we have done for Industrial and Commercial Customers