Cycle Test Stand using CompactDAQ and LabVIEW

Overview

Cycle Test Stand using CompactDAQ and LabVIEW. A manufacture of home water purifiers needed custom LabVIEW software to cycle test their product. The cycle test controlled water flow and electrical power via relays to the units under test. The current draw of each unit was monitored and saved to file. The user needed the ability to test groups of units independently of each other. The program was going to be used in different locations all over the world and needed to be understood by non-native English speakers.

Solution

We developed a custom LabVIEW program that controlled the relays and measured the current using NI CompactDAQ hardware. A CompactDAQ system has a chassis that is connected to a PC through USB or Ethernet, and then populated with one or more conditioned I/O modules that provide direct sensor connectivity.

Example of CompactDAQ hardware

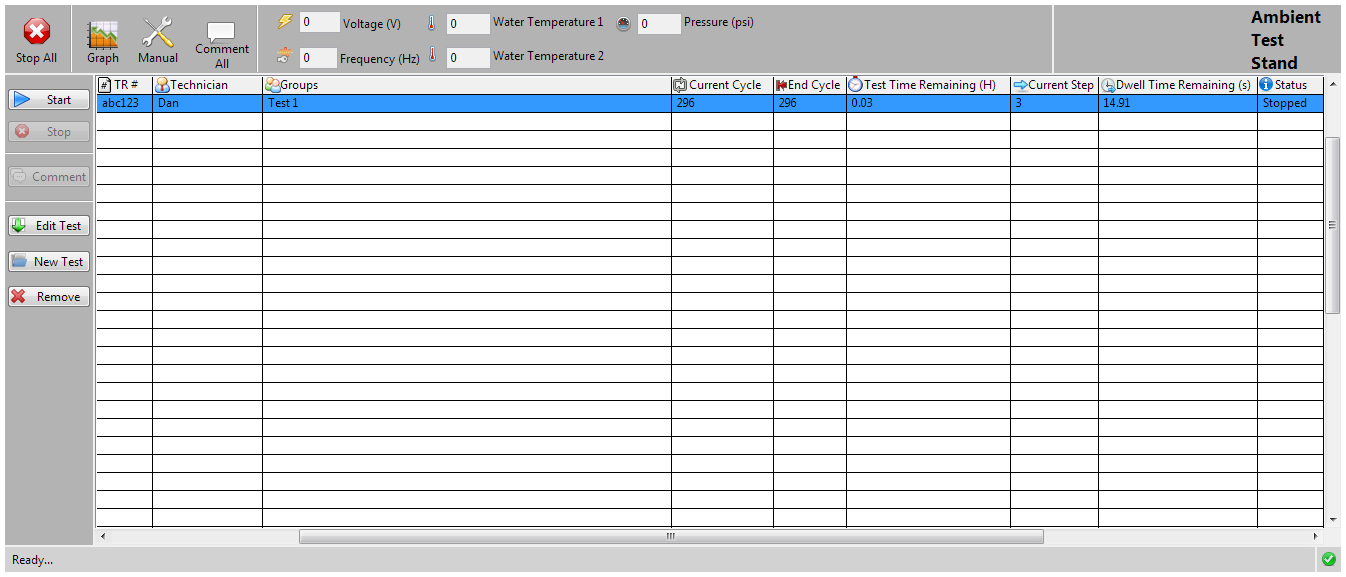

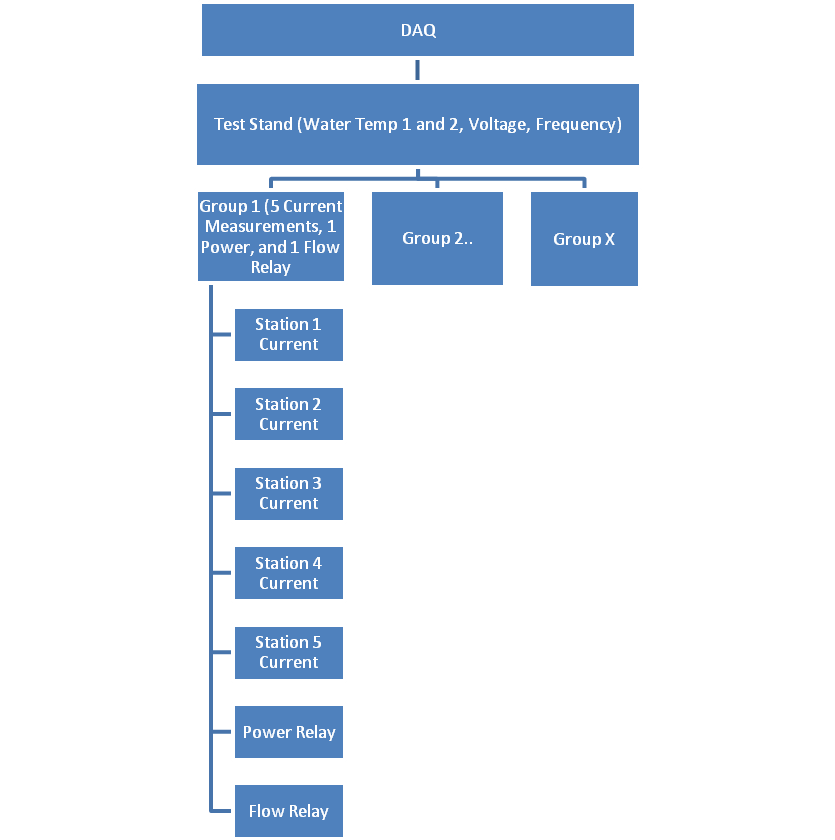

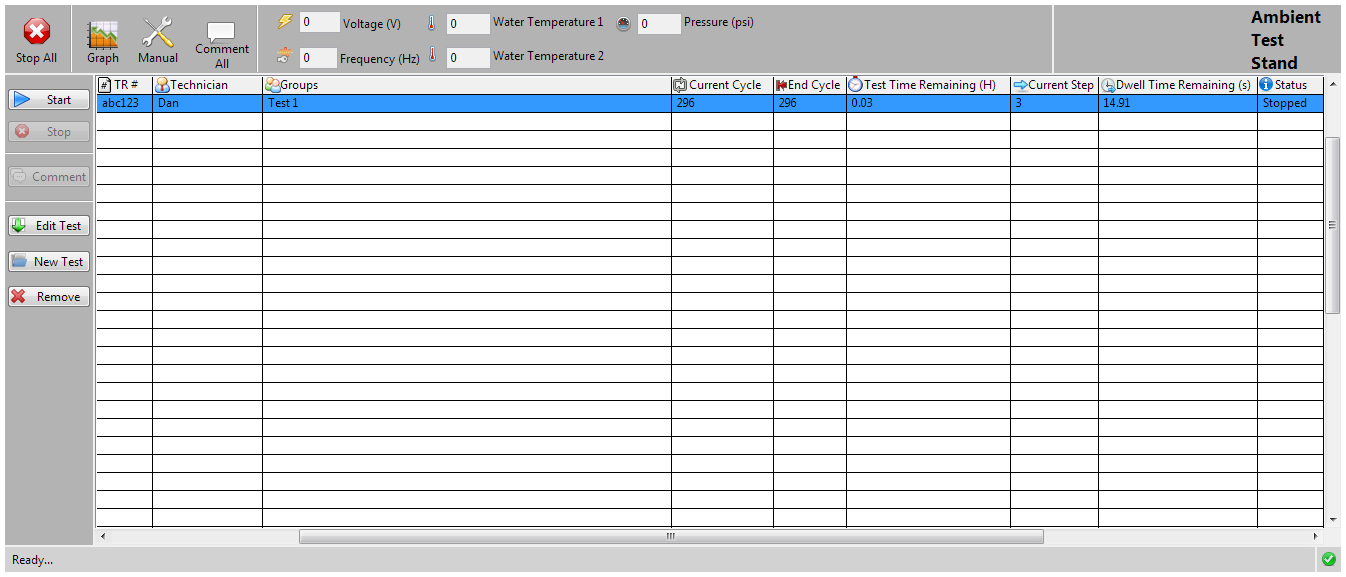

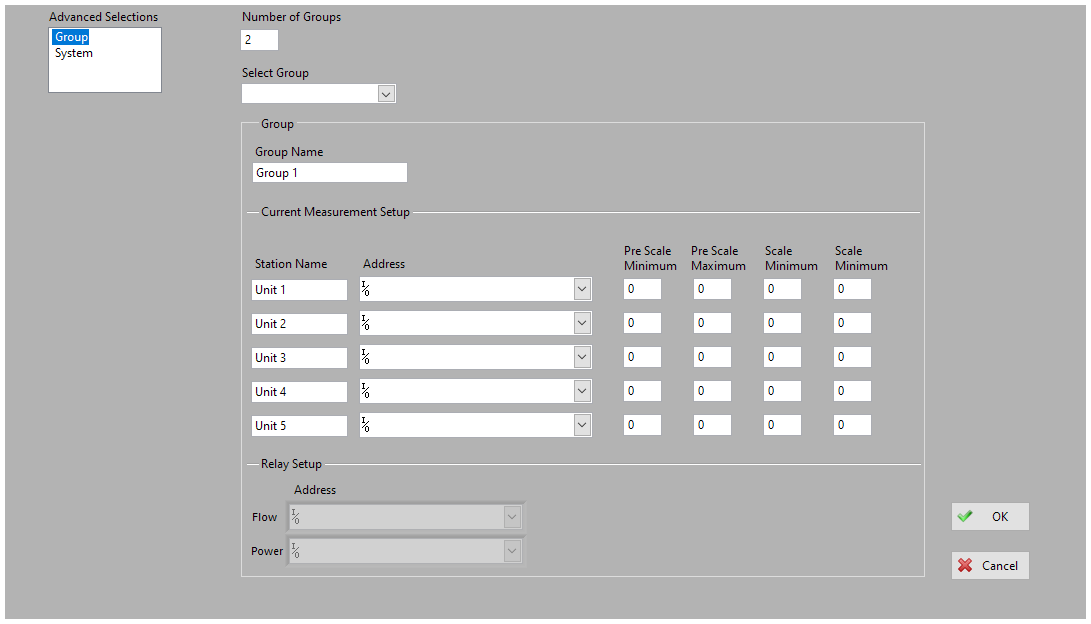

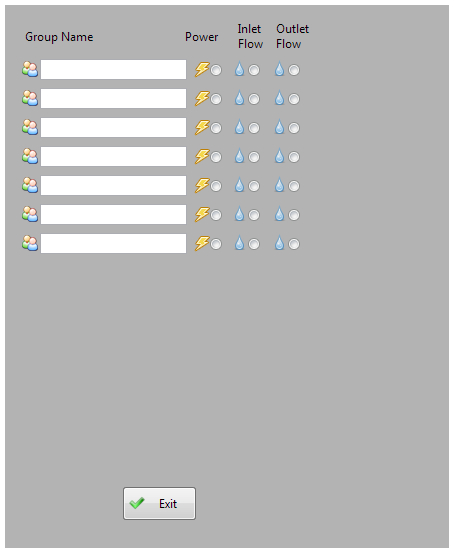

We architected the software so groups of units could be tested independently of each other. A group consisted of 5 units. Power, and water flow control relays were controlled for each group. The electrical current draw for each unit was monitored. The user could create, edit, start testing, and stop testing each group. This allowed the customer to run different tests on groups of units instead of testing all the units at the same time.

Block Diagram of System

The program utilized icons to communicate functionally in a graphical way. This allowed the program to be easily used by non-native English speakers.

Features

Main UI

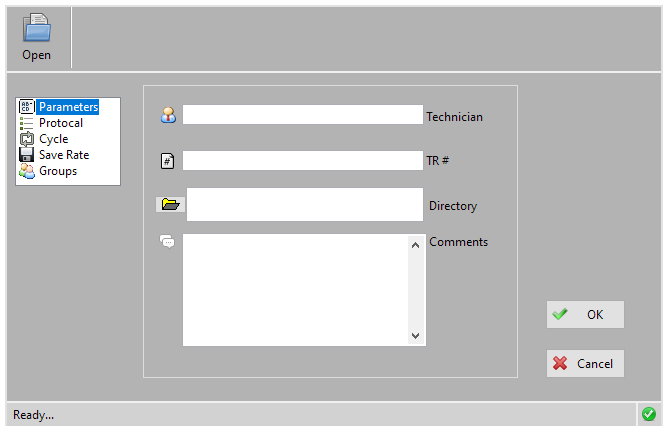

Test Editor

The test editor allowed the user to edit test parameters. The user could load a previously saved test setup file. Each group of parameters were organized so the user could select the group they wanted to edit. This made the dialog easier to use because the user could focus on just the group of parameters they wanted to edit.

Test Editor Dialog

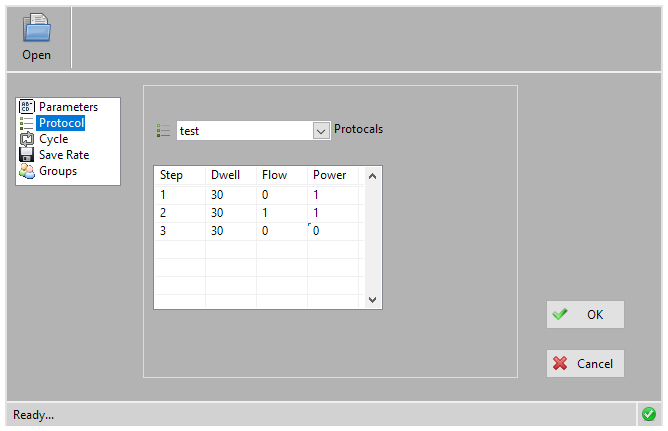

Test Editor - Protocols

The protocol defined the cycle for each test group. The protocol contained the dwell time which was how long each step was executed and the state for the flow and power relays during that step. The protocol was saved as a text file that could be edited in Excel or Notepad by the engineer. A drop down list of the available protocol files was provided so the user could select what protocol they wanted for the test.

Test Editor - Protocols

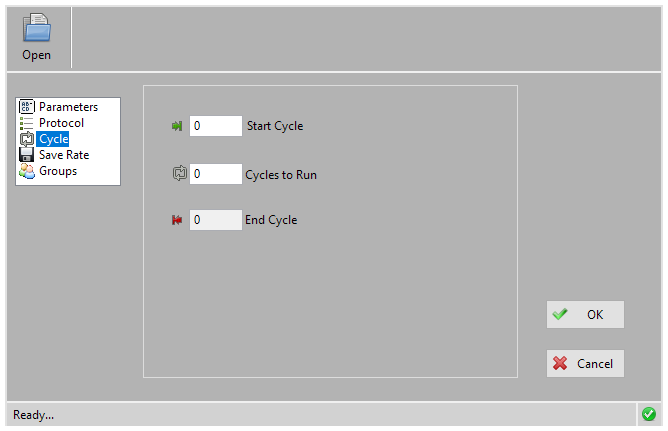

Test Editor - Cycles

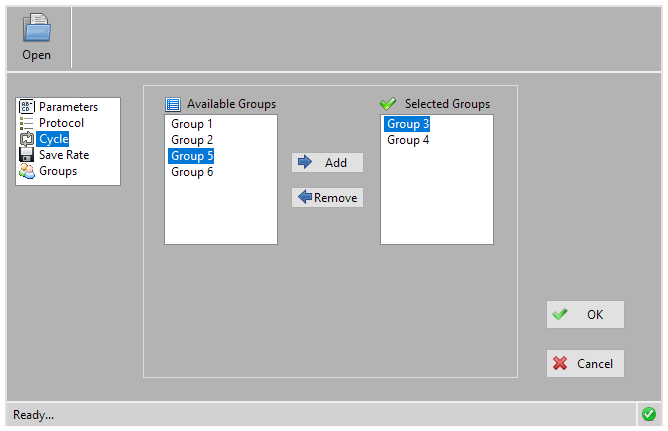

Test Editor - Groups

Test Editor - Groups

Advanced Settings

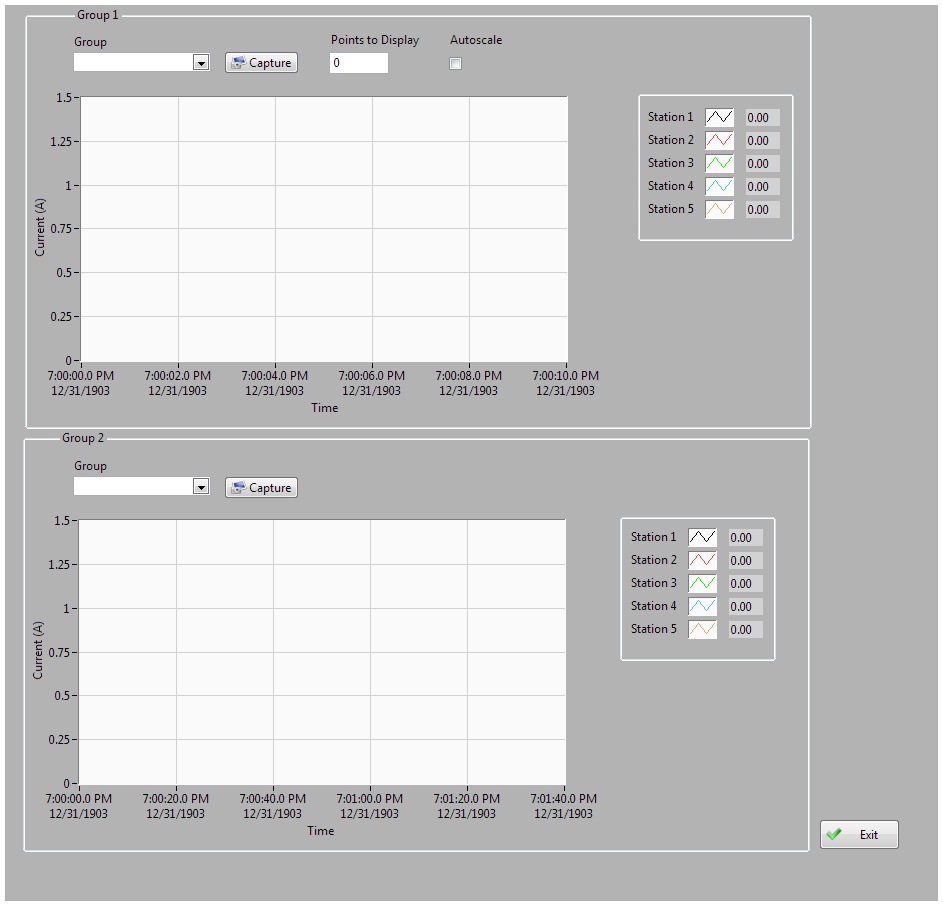

Graph Dialog

Graph dialog allowed the user to select a group of units and plot the data collected for each unit in the group. The user could also save a screen shot of the graph to file.

Graph Dialog

Manual Dialog

Manual Dialog

Result

Let's build an application together. Contact us today

- Learn how we do a project

- Lean about PC based data acquisition

- Learn more about CompactDAQ

- Learn more about LabVIEW

- Learn about other test systems we have done for other customers