Pressure Cycle Test using LabVIEW and CompactDAQ

Overview

Pressure cycle test using LabVIEW and CompactDAQ. A research and development firm needed a custom LabVIEW application to cycle their product. The program needed to perform 3 separate tests on the units under test. The software had to independently monitor up to 10 test stations stations.

Solution

CompactDAQ was chosen for the data acquisition hardware. A CompactDAQ system has a chassis that is connected to a PC through USB or Ethernet, and then populated with one or more conditioned I/O modules that provide direct sensor connectivity.

CDAQ Chassis

We developed a custom LabVIEW application that performed 3 different tests on the customer's product. Each different test could be selected and ran from the main screen. The test contained 10 stations that were independently monitored. The user could enable or disable each test station depending on if the station was populated with the test unit.

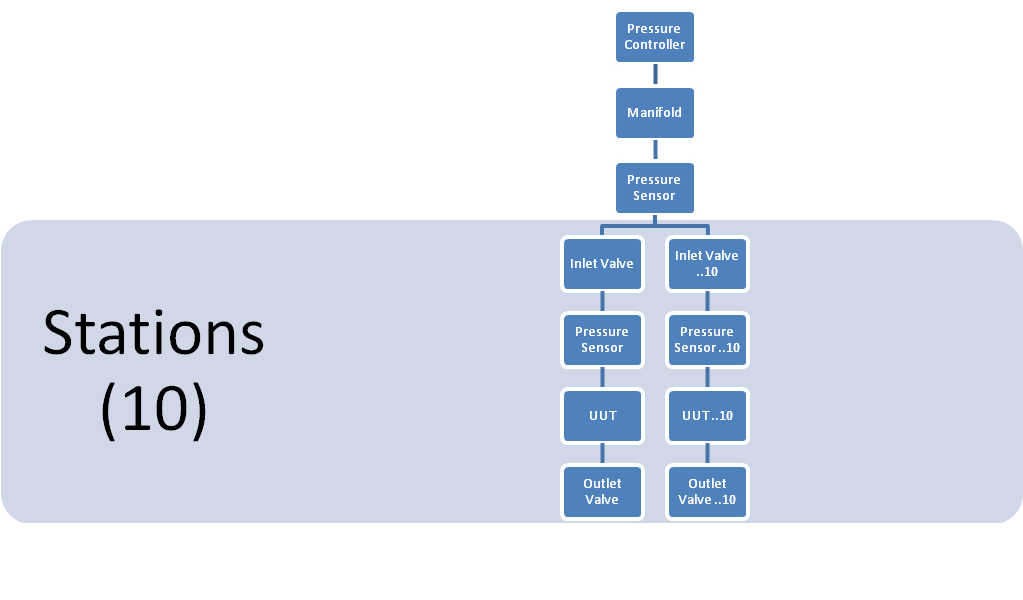

Test Station Block Diagram

Features

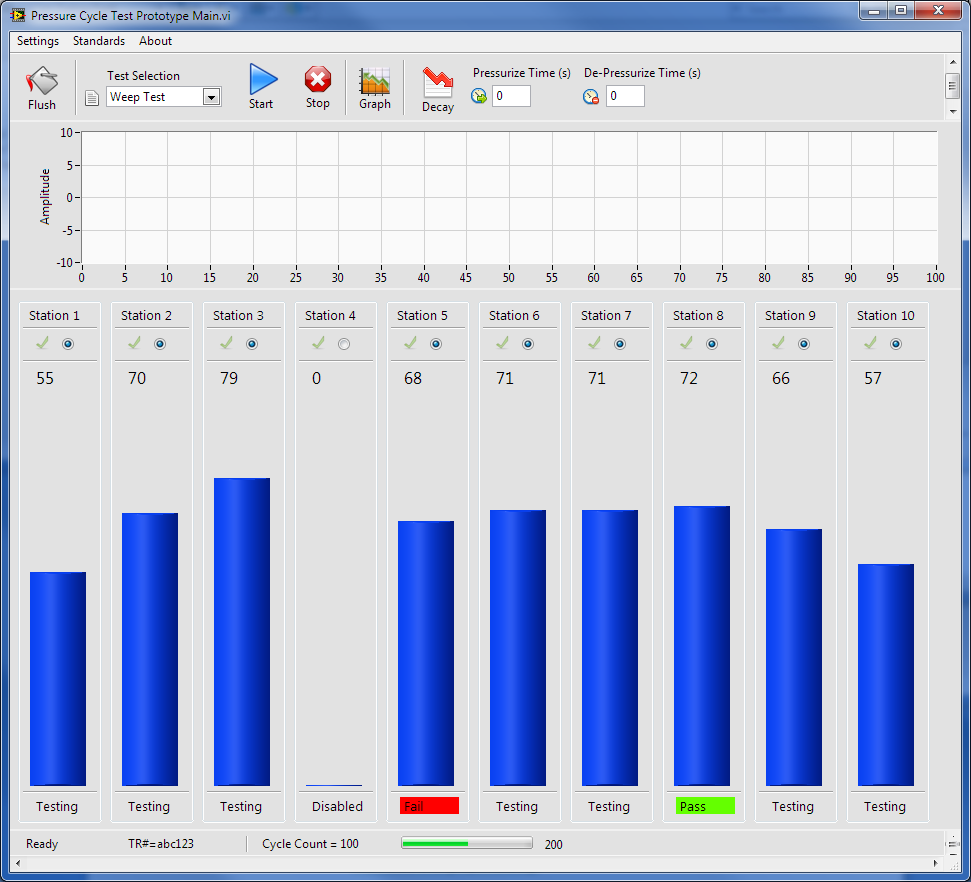

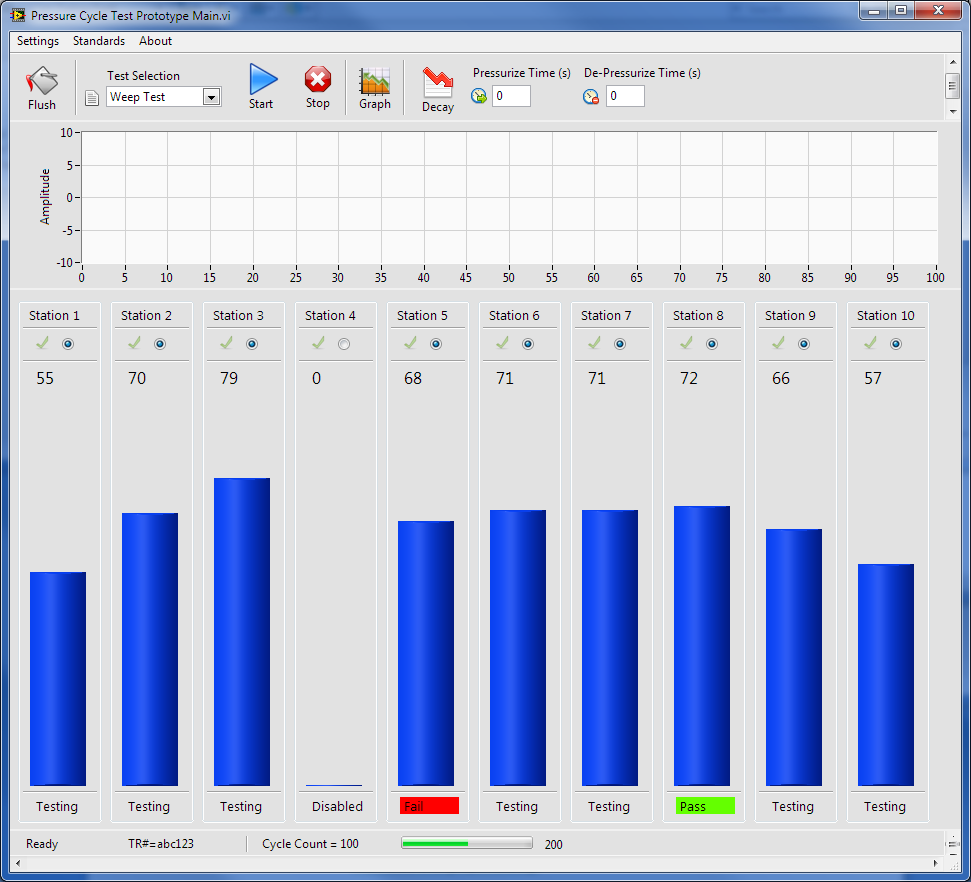

Main

The main screen allowed the user to view the current status of the test stations and had the ability to configure the test. There were 3 test selections the user could choose. The main screen also displayed the current pressure for each station. The user could disable or enable each station depending on if that station was populated with a test unit. This made the test extremely flexible because the user could just populate as many test stations as needed.

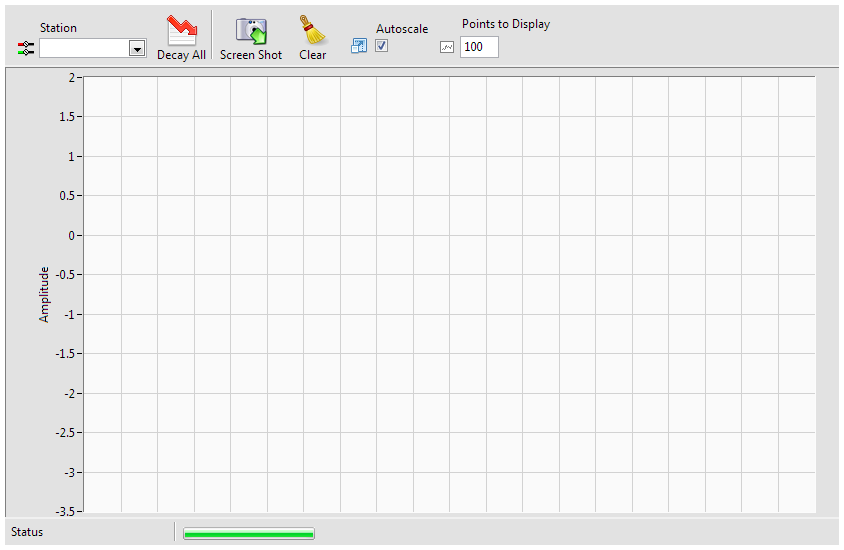

Graph Dialog

The graph dialog allowed the user to view a graph of the pressure with respect to time on an individual test station. The graph dialog was independent of the main test i.e. the test could be running and the user could view the graph dialog without interfering with the rest of the test.

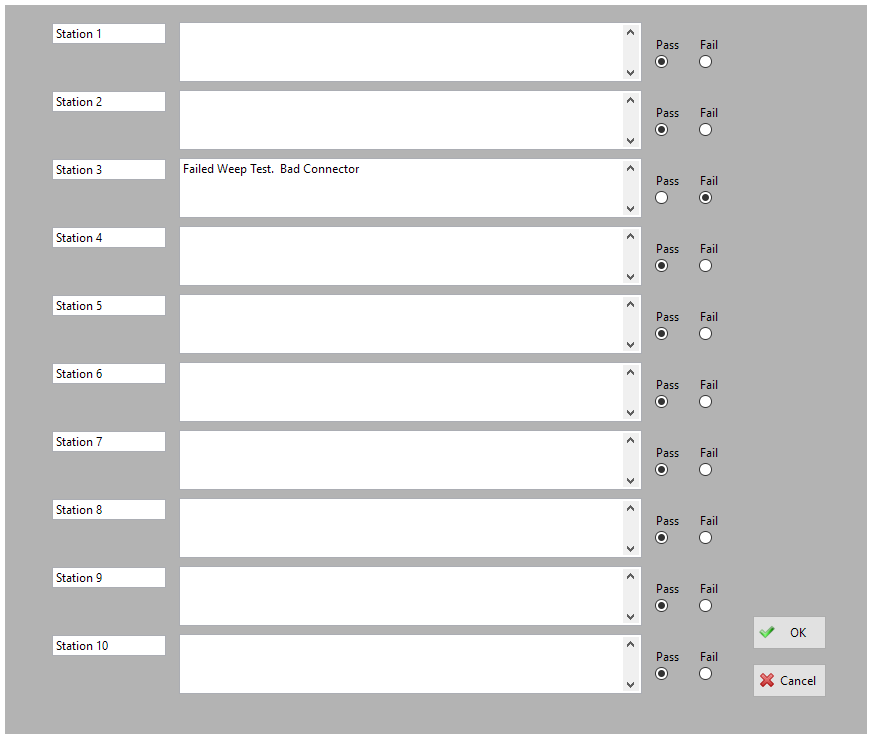

Test Results

The test results dialog was displayed after the completion of a test. The dialog indicated whether the test pass or failed and allowed the user to enter comments about the test. The data from this dialog was saved to a comma separated value file (.csv).

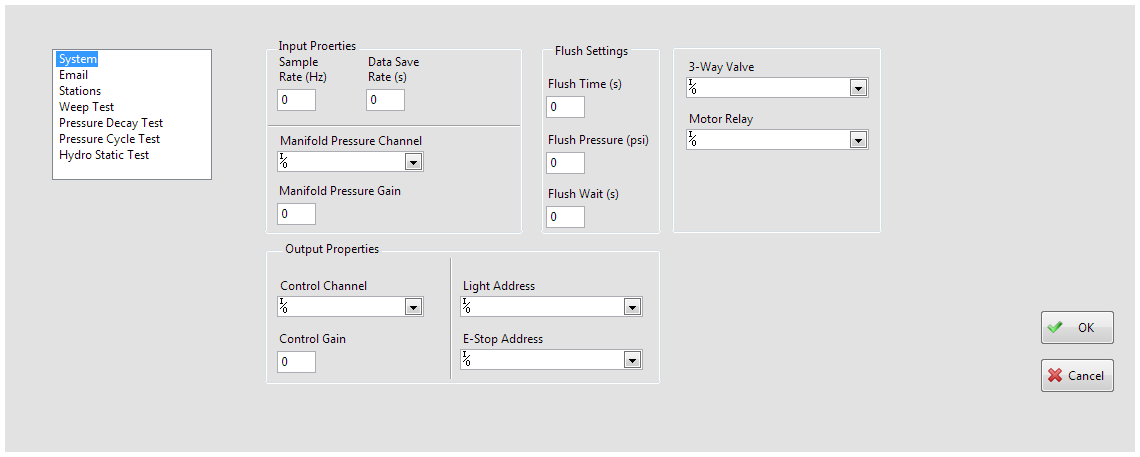

Options

The Options dialog allowed the user to set hardware and test settings.

Result

Pressure Cycle Test using LabVIEW and CompactDAQ allowed the customer to test their product efficiently. The system automated their functional test of their product greatly increasing data they were gathering on the product's performance. We wrote the software with a modular and scalable architecture so it could accommodate additional tests in the future.

Let's build an application together. Contact us today

- Learn how we do a project

- Lean about PC based data acquisition

- Learn more about CompactDAQ

- Learn more about LabVIEW

- Learn about other test systems we have done for other customers